Collector is the app of choice for tracking and traceability in the Esri Utility Network. We had to upgrade to a device and GPS receiver that supported Collector.

user story

AltaGas Utilities Upgrades Digital As-Built Process for Tracking and Traceability

AltaGas Utilities (AUI) is a regulated Canadian natural gas distribution utility with over 13,000 miles (21,000 km) of pipeline across Alberta. To prepare for potential forthcoming industry standards for tracking and traceability, its GIS team has spent the past three years updating its digital as-built process for polyethylene (PE) pipe to comply with industry standards for bar code scanning.

Challenge

In 2015, natural-gas industry leaders published ASTM F2897, a 15-page collaborative document specifying how pipeline attributes should be identified via a standard, 16-digit barcode.

“ASTM F2879 is the standard that the gas utility industry is rallying around to address the requirements of tracking and traceability,” said Tom Coolidge, Esri Director of Gas Utility and Pipeline Industry Solutions.

Compliance with ASTM F2879 requires a method for barcode collection and storage.

User

AltaGas Utilities, Inc.

Partner

Eos Positioning Systems

Challenge

Updating field technology for tracking and traceability compliance

Solution

Collector for ArcGIS, Arrow Gold GNSS, ArcGIS Utility Network Management extension

Results

Reduces as-built time by 50%, enabled regulatory compliance proactively

Partner

Eos Positioning Systems is an Esri Silver Partner and Canadian manufacturer of Esri-aligned GPS/GNSS receivers. The Eos Arrow Gold GNSS provides centimeter accuracy with RTK corrections or submeter accuracy via free SBAS (WAAS) corrections. AUI chose the Arrow Gold because of its reliability in Canada’s harsh environments.

“We have 22 Arrow Gold receivers in the field and they work flawlessly, even in our winter months” Said Mathew Desbiens, AltaGas Utilities Manager, GIS.

Solution

Esri’s ArcGIS Utility Network Management extension and mobile apps have been enhanced to streamline ASTM F2879 compliance.

“We wanted to move to the Utility Network for our GIS because Esri made it directly compatible with the ASTM-F2897,” said Desbiens. “There is already a field with associated domains for every required attribute in Esri’s Utility Network schema.”

Moreover, the latest Collector release was enhanced with Arcade scripting to display decoded barcode data in the field, even in disconnected areas.

“To support Collector, we upgraded to a device and GPS receiver,” said Desbiens. Desbiens paired Collector with the Eos Arrow Gold GNSS on Samsung Galaxy Tab Active 2 tablets to replace their legacy, all-in-one GPS data collection devices.

“The recent improvements to Collector can result in a simpler and more efficient tracking and traceability workflow, when combined with an ArcGIS 10.7 or higher enterprise geodatabase,” said Tom DeWitte, Esri Natural Gas Industry Technical Lead.

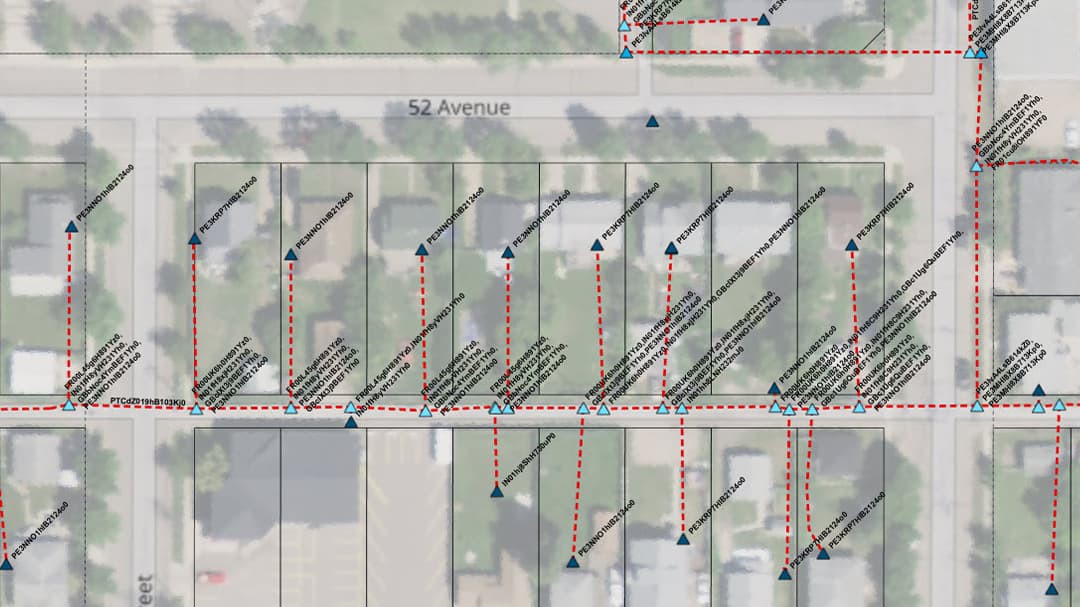

Image description

Image description

Results

After three years of working with Esri and Esri Canada, which included participation in the Utility Network beta program, AUI rolled out the new field data collection system to 50 contractors and employees.

In the past, all contractor as-built work needed to be physically uploaded at an AUI office but now collector allows contractors to sync data in the field directly to a secure server in the cloud.

“You had to work for the company (AltaGas Utilities) to access real-time data,” Desbiens said. “Now, independent inspectors who already visit installation sites can collect as-builts and sync data real-time.”

Just by scanning a barcode and getting rid of dropdowns, AUI is saving 50% of their inspectors’ field time and reducing the potential for human error. “This made our business case very clear,” said Desbiens.

In addition, the ongoing cost of GPS hardware and services have been “significantly” reduced.

“In the past, every time a screen broke, we had to buy an entire new GPS receiver,” said Desbiens. “With the new setup, I could just pull another tablet out of the box and they could keep going.”

GIS Editors, in the AUI office, then use a custom geo-processing tool in ArcGIS Pro to decode the collected barcode into its tracking-and-traceability attributes (e.g., manufacturer, lot code) based on tables within the ASTM F2897 document.

“Collector will automatically decode the barcode, auto-populate the derived attributes, and display the information immediately after the new GIS feature is submitted by Collector,” said Doug Morgenthaler, Esri Program Manager for Collector.