Many utility owners struggle to obtain a comprehensive overview of their sewer networks. This is because they often only have access to static documents that give no context for the condition of their pipes or where the pipes are located in the network.

National engineering firm and Esri partner Burgess & Niple (B&N) has built a dynamic tool in ArcGIS that, when paired with the company’s artificial intelligence (AI)-powered pipe inspection app, creates a digital twin of a utility’s entire sewer system. The result is that utilities get a complete overview of their networks, along with access to inspection videos and images. This allows utilities to make data-driven decisions about their pipes, including when and where to invest in asset rehabilitation or replacement.

The Town of Newburgh, Indiana, recently used B&N’s AI software platform, called PipeAId, to help with the annual inspection and cleaning of its sanitary collection system. In addition to saving staff time and capital, the digital twin is helping Newburgh’s sewer department level up its pipe inspection processes.

Accurate Observations and Unbiased Assessments

To examine sewer pipes, inspectors can send closed-circuit television (CCTV) cameras through them to record pipe conditions. Inspectors typically document their observations in the field and again while doing quality assurance/quality control (QA/QC) of the video back in the office. They use codes from the Pipeline Assessment Certification Program, established by the National Association of Sewer Service Companies (NASSCO), to standardize their observations. There are more than 230 NASSCO observation codes to choose from, and they are often paired with additional data.

Despite this push for standardization, observation accuracy remains an issue. Human subjectivity can also be a problem. For example, inspectors must differentiate between cracks, fractures, and breaks; determine the severity of root interference; understand whether a tap is defective; and address other issues. An experienced inspector is more likely to accurately document these observations than someone new to the job would be.

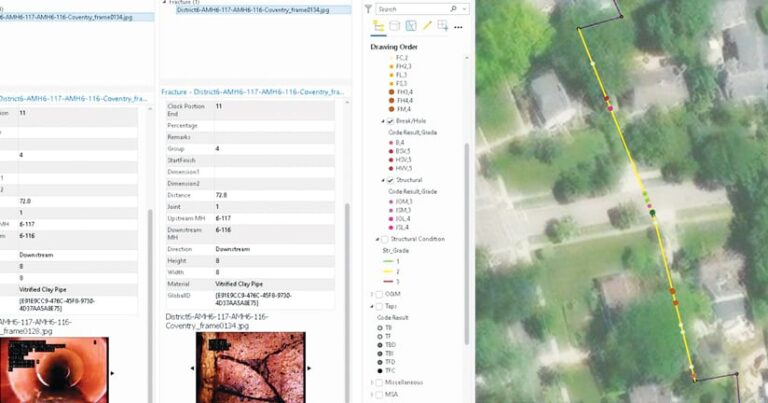

PipeAId is designed to help utilities process their CCTV video in a way that’s more accurate and less subjective than manual processes are. It examines the video and extracts data on sewer pipe obstructions such as cracks, roots, and taps. When a defect is present, PipeAId maps where the defect was recorded in a computer vision and machine learning environment, and the AI model determines which NASSCO defect code applies.

All this inspection data—along with the supporting images and videos—is provided to utilities via a digital twin in a desktop ArcGIS environment, such as ArcGIS Pro. To achieve this, when working with a client, B&N’s development team leverages geoprocessing tools in ArcGIS Pro to create a geodatabase of the client’s sewer conditions. Relevant images (stored in a geodatabase) and videos (stored in the cloud) are linked to each observation and pipe segment. When all the observation data is paired with B&N’s data hosting solution, staff and contractors at the utility can access the inspection information in the office or out in the field with just a few clicks or taps on their devices.

PipeAId is designed as an out-of-the-box solution for ArcGIS users, so utility owners don’t necessarily need to invest in new software. Instead, they can leverage their own GIS deployments without relying on other third-party software to store data. B&N can also deliver the solution with Esri’s AEC Project Delivery subscription service, customizing the data to clients’ unique needs while setting them up for future growth.

Increased Transparency for Newburgh

In Newburgh, staff members in the town’s sewer department inspect and clean portions of the sanitary collection system annually. In 2023, they used PipeAId for the first time to process inspection data for 40,000 linear feet of the town’s pipes. This has allowed staff members to get an unbiased condition assessment of the town’s buried assets, enabling them to maximize their pipes’ life span and either rehabilitate or replace them before failure occurs.

Additionally, staff members leveraged the PipeAId-generated digital twin, which can be integrated with the town’s GIS to show the pipes’ size, material, inspection date, and condition, along with the location of each observation and defect. This provides a high level of transparency for each pipe’s condition and gives leaders in the town’s sewer department reliable information so that they can make data-driven decisions on Newburgh’s pipe maintenance strategies. Having all this information available on maps—even on mobile devices—also helps mobile staff members facilitate conversations with residents and better inform stakeholders about the town’s proactive pipe maintenance program.

“This AI system is taking our sewer pipe assessment program to the next level, and we look forward to a far more efficient and cost-effective sewer inspection process,” said Steve Shoemaker, the sewer commissioner for the Town of Newburgh. “By using the CCTV data that we’re already gathering and translating it into a more useful format, it’s making the utility’s efforts more valuable, providing a high level of service to our customers.”

Keeping Community Members and Stakeholders Informed

Using GIS to design a digital twin of a sewer system, complete with easy-to-understand maps and dashboards, is helpful for when utility staff members need to explain complex sewer system concerns to community members and stakeholders, as staff at Newburgh have done. People get a big-picture view of their area’s sewer systems, along with highly detailed information that shows how utility owners are making informed decisions about which pipes to rehabilitate and replace, and when.

“GIS is able to take thousands of pieces of information and put them into a usable format so utilities can take advantage of the information they already have to complete cost-effective maintenance,” concluded Brenton Hasenour, B&N’s water and wastewater section director in the firm’s Evansville, Indiana, office.