Global Professional Services Company Uses Esri Technology to Record Rockfall Hazards

The Main Western Line is a railway that runs from Central Station in Sydney, Australia, up and over the Blue Mountains to western New South Wales and beyond.

The line carries passengers and freight out of Sydney and also into the city from as far west as Perth, 4,352 kilometers away on the opposite side of the Australian continent. At various locations in the Blue Mountains, the line is cut into massive sandstone cliffs, with sections at the localities of Zig Zag, Lapstone, and Glenbrook running alongside subvertical cliff faces that reach up to 60 meters high.

The natural cliff faces and sandstone cuttings adjacent to the railway line present a rockfall hazard to the trains and overall railway operations. To collect data on these hazards, a team from the global professional services firm GHD turned to ArcGIS Survey123, a mobile data collection app from Esri.

A Constant Hazard

When even small rocks tumble down a cliff and onto a railway track, there’s a possibility they will cause trains to derail and the line to shut down for several hours, potentially creating a rail traffic backup for both commuters and freight.

To minimize the risk of rocks falling along the Main Western Line in the Blue Mountains, the cuttings—made in the rock to make way for the railway—need to be assessed at least twice per year. Inspectors in the field look for indicators that the rocks may be loose; these indicators may include cracks in—or roots growing into—the rock face.

The findings help identify what remediation actions need to be taken. This could include the installation of rockfall mesh, reinforced shotcrete, or rock bolts to secure problem rocks. Removal of existing vegetation may also be recommended, as the roots of trees and shrubs can loosen rocks.

The railway owner tasked GHD’s geotechnics team with assessing the condition of the rock cuttings for three years, starting in May 2019. GHD operates in the global markets of water, energy and resources, environment, property and buildings, and transportation. The company provides engineering, architecture, environmental, and construction services to clients in the public and private sectors.

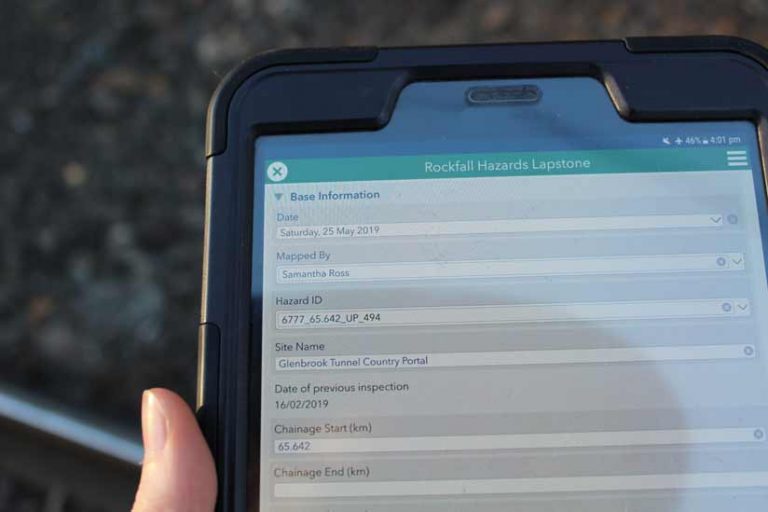

The GHD geotechnics team, working with the GHD digital team, decided to use ArcGIS Survey123, a mobile data collection app, to digitally collect the data rather than record the information with pen and paper. The team members thought a digital app would be faster and easier to work with out in the field and save them a significant amount of time when they reported the data. They’ve used ArcGIS Survey123 to complete three inspections so far.

Previous inspections of this kind had been conducted with pen and paper, and—as they would potentially be walking up to 8 kilometres in one day—the team wanted a way to reduce the need to juggle clipboards, cameras, field tools, and hundreds of past reports.

Over 500 individual rockfall hazards had already been identified in the three localities during past inspections. The first inspection conducted by GHD needed to incorporate an assessment of all of these hazards, details of which were provided in PDF reports. That previous hazard data was entered into ArcGIS Survey123 for easy reference during the inspections and used for later reports.

The inspections involve various team members collecting data in the field, so a standard, easily repeatable method for data collection was needed. The client requested the final deliverable as a PDF report, so the data collected needed to be easily converted to reports with minimal data entry and manipulation.

“Survey123 . . . has been fantastic for collecting large amounts of data in the field and has solved the dreaded juggling of clipboards and mass amounts of printed documents. Being able to use Survey123 on any device, be it a company-owned tablet or personal mobile phone, has made it very user friendly for the field team. The switch from ‘pen and paper’ to Survey123 has possibly cut field inspection times in half.”

The rock cuttings are only visible from within the rail corridor, and the inspections must be carried out on foot within a limited time frame. Due to high freight traffic and weekday commuter and weekend tourist patronage on the line, particular sections of the Main Western Line in the Blue Mountains are shut for only four weekends per year for maintenance. That meant the field data capture solution had to be time efficient.

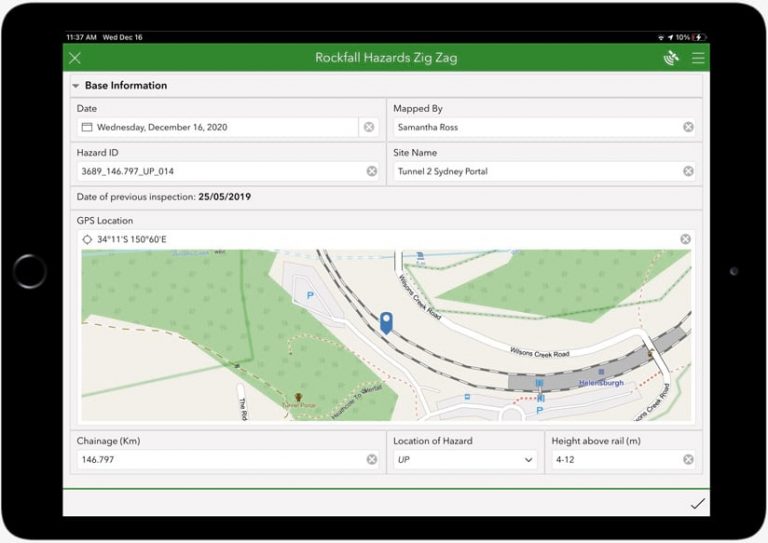

The geotechnics team chose ArcGIS Survey123 to enable efficient and detailed data collection on a smartphone or tablet. Each hazard, such as a loose rock at the top of a rock cutting, was assigned a unique number ID. By selecting this ID in a drop-down menu at the top of the form, almost all subsequent fields in the form were populated with the existing information from a reference spreadsheet.

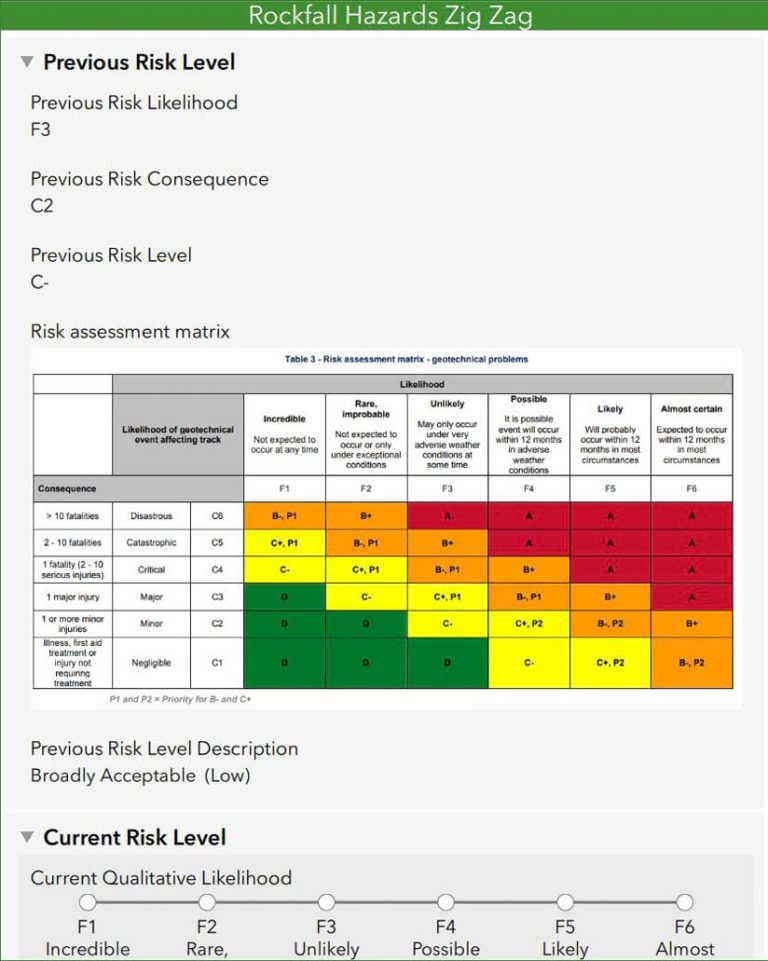

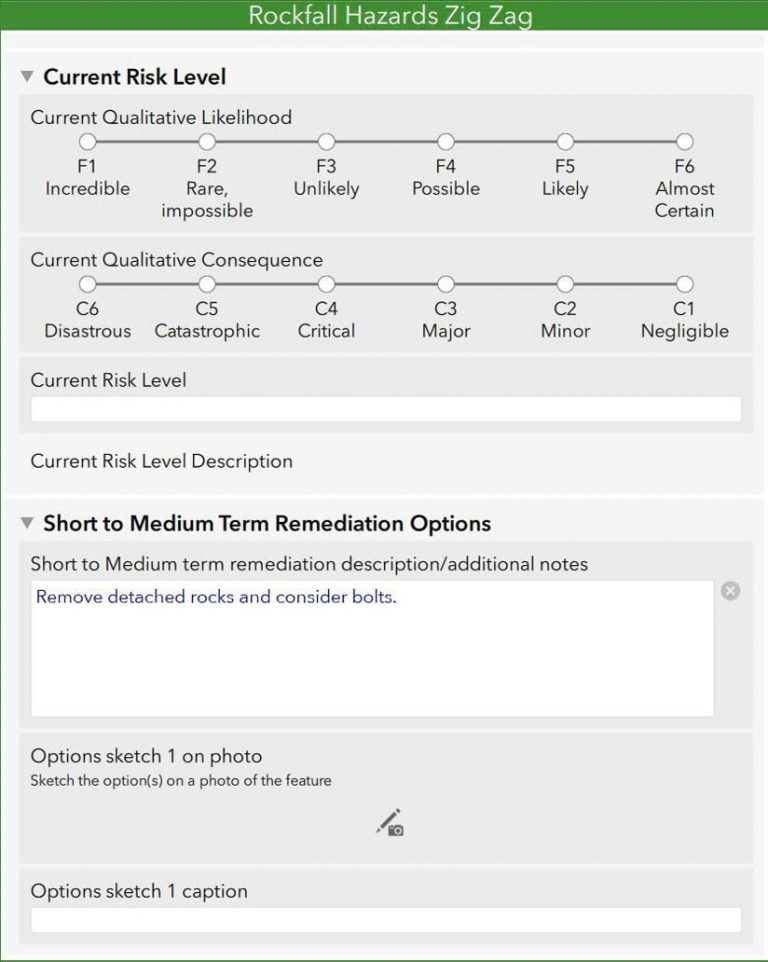

Inspectors in the field could then look at the survey form, see all information pertaining to the hazard, and edit the entries as required, rather than needing to enter all the information from scratch. The inspectors were required to take the hazard’s photo, which is then attached to the form, and enter the current risk rating during each inspection, as this forms the basis of the assessment. The rating is determined from a risk matrix combining the likelihood of a rockfall affecting the track, and the severity of the rockfall if it happened.

For subsequent inspections, data that the geotechnics team had collected populates the fields in the survey form, based on the unique ID. From there, the user could edit the inspection information if necessary, or select No Change, allowing for quick data capture.

Photos taken in the form could be annotated, if necessary, to indicate certain features—for instance, drawing a circle around a rock of interest—or to highlight potential remediation options, including marking the recommended location for rock bolts. High-resolution photographs of the hazards were attached to each record, and the inspection data was then presented using a custom feature report template.

A Real Time-Saver

The ability of ArcGIS Survey123 to populate fields based on existing data saved staff a lot of time in the field, as all the information needed to make an assessment was displayed on a smartphone or tablet. GHD’s team in the field quickly adapted to the new method of data collection, and inspections were ably completed within the restricted time frames.

This method of data collection was reliable and repeatable, and it contributed to a huge time savings overall. Some of these sites had been inspected by GHD in 2007 and 2017 by staff using pen and paper. Using ArcGIS Survey123 for this round of inspections in 2019 and 2020 has reduced the time spent to complete the work by half and lowered the total cost of the project.

“Survey123 has been a marked improvement in the way we gather information for our asset management or risk assessment projects,” said Jason Hellmuth, GHD senior geotechnical engineer and project manager for the job. “[By improving the efficiency of the data entry and reporting processes . . . [it’s] allowing us to deliver these projects in a more timely and cost-competitive manner for our clients.”