The Inner West Light Rail (IWLR), located in the heart of Sydney, Australia, runs for 8 miles (12.8 kilometers) predominantly along the corridor of a former freight railway line. The passenger transit service stops at 23 aboveground and underground stations as it goes from Sydney’s central business district, past the tourist area of Darling Harbour, and out toward the suburb of Dulwich Hill.

The overhead wiring structures and sections of slab track that make up the IWLR need to undergo regular structural evaluations. In May 2019, Esri partner and professional services company GHD was commissioned to undertake this routine assessment. The project required GHD to evaluate every single overhead wire and slab track in 10-foot (3-meter) intervals. The company then had to put together individual PDF reports for each asset and section of slab track.

To do this, GHD planned to dispatch a team of field engineers to carry out the inspections over the course of a month. The engineers needed to be efficient and collect consistent data across the board. But this was difficult because each inspection period was often constrained by how long the railway could be shut down. What’s more, preceding assessments had been conducted using pen and paper, along with digital cameras. Data was manually entered into a spreadsheet-based reporting template, and there was no easy way to match similar-looking photos with the correct assets.

GHD set out to find an innovative mobile solution that would allow its dispersed field team to capture consistent data across numerous inspections and generate simple reports, with photos, to give to the client. ArcGIS Survey123 ended up fitting the bill.

Consistent and Comprehensive Data Collection

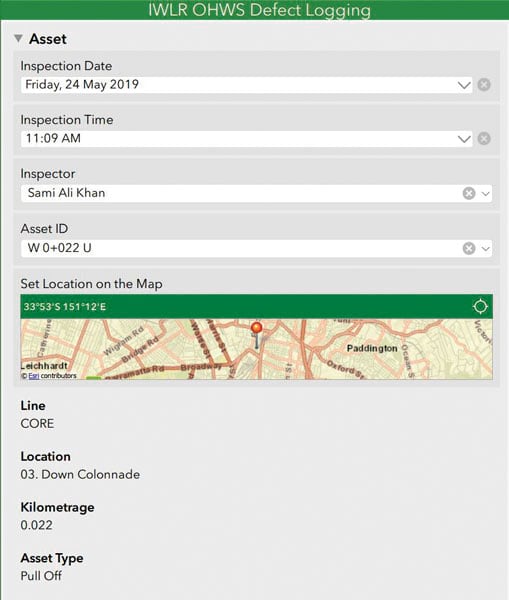

Using Survey123 Connect for ArcGIS, the location intelligence group in GHD Digital created two custom forms for Survey123 to ensure that field engineers could collect consistent data across teams and inspection periods. The first was for the slab track assessment and the second was for the overhead wiring evaluation—and each contained feature-specific questions that applied only to the type of inspection being conducted. Both surveys were available offline, too, which was indispensable for inspectors who conducted assessments from tunnels that lacked mobile reception.

Accessing one of the two surveys on a tablet or smartphone, an inspector would select an asset’s unique ID from a drop-down menu. Client-supplied information pertaining to that asset was then prepopulated into the form. From there, the survey guided the inspector to make observations about the asset and take photos of it from specified angles.

This combination of customized drop-down menus and free response text sections enabled inspectors to record consistent data while capturing other comprehensive details that could otherwise get overlooked. Inspectors also had access to reference tables that were embedded as images into the survey so they could quickly find definitions, repair priorities, and other asset characteristics that they were required to fill out. The survey collected data about asset defects in a repeat table, so there was no limit to the number of defects they could document for a given asset.

“Survey123 streamlines the repetitive motions of structural assessments, making my job quicker and easier,” said Andrew Bell, one of the field engineers at GHD.

Upon completing the field data collection campaign, lead engineers reviewed all the submissions using ArcGIS Online. Employing the Survey123 feature report service in ArcGIS Online, the location intelligence group then created a feature report template to automatically generate the reports about the wire assets and slab tracks—complete with corresponding photos—in minutes.

Time Saved Reduces Risks

GHD’s field engineers were able to adapt quickly to this new method of data collection. They found that having the prepopulated asset details gave them the background information they needed to kick-start their assessments. The surveys also made it clear which questions required responses and how to answer them appropriately. Embedding the reference tables into the form also eliminated ambiguity about assessment guidelines and made it so inspectors didn’t have to flick between screens to find those specifications.

Ultimately, using Survey123 saved field engineers time and resulted in their employing consistent terminology throughout their reports. This wouldn’t have been possible had they collected data using pens and paper.

“Using Survey123 for data collection was significantly easier than collecting data manually for such a large area as [was] assessed in this case,” said Olivia Britt, a member of GHD’s field team. “It was helpful to be able to preprogram object types and intervals/nodes for data collection [and] to be able to collect data about discrete objects, [such as] individual wiring structures, and continuous objects, [such as] track intervals, using one program.”

Furthermore, the time-saving features that come with Survey123 limited the team’s exposure to the risks associated with doing data collection in the light-rail corridor. And being able to automatically generate complete reports on each asset, thanks to the Survey123 feature report service, was invaluable.

The ability of ArcGIS Survey123 to extract specific collected data and photographs and produce preformatted standard reports for each asset was a powerful feature, which produced quality reports and saved on reporting time, according to GHD geotechnical engineer Sami Ali Khan.