Headquartered in British Columbia, Canada, Tolko Industries is a leading manufacturer of lumber and sustainable wood products. At its operations facility in High Level, Alberta, the annual harvest season runs from November to March. During this time, Tolko and its contractors harvest the volumes of timber its sawmill processes for the remainder of the year.

Tolko woodlands operations supervisor Michael Morgan is always looking for new technology to help the team increase productivity and meet demand for raw logs at mills.

“Anytime we see the market introduce new technology, we assess if there are opportunities to make our company more competitive and productive,” Morgan said.

For 20 years, this open-mindedness has driven Tolko to innovate with geospatial technology.

A Challenging Mapping Environment

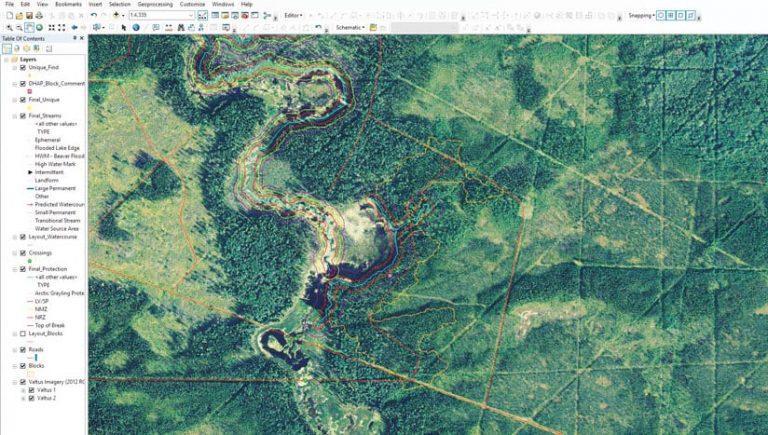

Within the province of Alberta, Tolko operates mostly on Crown (public) land. Prior to the start of the winter harvest season, Tolko staff members complete and submit a series of Forest Harvest Plans (FHPs) for provincial government approval. The FHPs must include maps of the proposed cutblock boundaries—the area in which they’ll harvest the timber—complete with an inventory of topographic features, such as roads, waterways, pipelines, and potential wildlife sites.

Before the FHPs are generated, mobile crews verify each boundary and topographic feature within the proposed cutblocks and confirm any required protection buffers. But creating highly accurate maps under a tree canopy can be particularly challenging in northern Canada.

In the early days of GPS, when Tolko first started mapping boundaries, its legacy, all-in-one GPS receivers could take hours to acquire and lock onto four satellites, the minimum number for the required level of accuracy. Even with enough satellites available, dense canopy made some signals unusable, resulting in downtime and productivity losses.

“In the field, our staff would spend a significant amount of time waiting for a reliable position from the GPS receivers available at the time,” Morgan said. “Additionally, there was significant postprocessing of the data in the office to get it into a deliverable format to be integrated into the development of the FHPs.”

If the data was reliable, Morgan could apply the required buffers in ArcGIS Desktop and submit the plans for approval. If not, the crews had to do more work.

At the same time, Tolko’s mobile staff had a second job: to mark, or flag, the cutblock boundaries by tying brightly colored ribbons around trees. But the ribbons posed their own challenges. For some operations, the flags need to remain visible for several years, yet wildlife often chew them off. In northern Canada, they can easily get covered by snow. If an operator misses any of these flags and crosses a boundary or protective buffer, there could be environmental damage.

“We could avoid a number of the operational challenges and increase operational efficiency by going digital,” Morgan said.

New Technology Increases Productivity

About five years ago, as part of a continual improvement initiative, Tolko presented the government with a business case to update its mapping technology. The company’s proposal included a combination of Web GIS based on ArcGIS software; highly accurate GPS data collection; and real-time data sharing of boundaries, topographic features, and buffers. With this digital mapping solution, Tolko could accurately map all protected demarcations while increasing productivity.

The proposal was accepted, and Tolko began looking for its real-time, handheld, digital mapping solution.

First, the company wanted to replace its GPS receivers. The new data collection system needed to have a larger screen with good overall visibility. After trying out a variety of devices over several seasons, Tolko decided that a combination of iPads and iPhones worked best, particularly thanks to the battery life that facilitates longer shifts during the limited seasonal windows.

To improve the iOS devices’ accuracy, Tolko tested a number of GPS receivers. Ultimately, the company selected the Arrow 100 GNSS receiver from Esri partner Eos Positioning Systems because it performed best in the challenging operating environment. Particularly important was the Arrow 100’s support of all four current Global Navigation Satellite System (GNSS) constellations, including the Russians’ GLONASS constellation. The increased number of usable satellites available under canopy helped greatly boost Tolko’s productivity and location reliability at higher northern latitudes.

“The Arrow 100 gains access to far more satellites by supporting all four constellations, which means higher accuracy and reduced downtime,” Morgan said. “For us, being a remote northern community where GPS satellites are a bit less visible, supporting a constellation like GLONASS was already a huge improvement.”

Being a heavy Esri software user, Tolko selected ArcGIS Collector as its app of choice for real-time data collection. The app not only eliminated manual data transfers to and from the field but also allowed Morgan to more rapidly verify the quality of the data being collected than his previous import/export workflow did. Because much of Tolko’s work takes place in areas without cellular coverage, mobile technicians perform their tasks in offline mode and then sync the Collector data with ArcGIS Enterprise at the end of each day.

Having the data in the cloud also allows Tolko to easily share its approved maps with logging contractors, which means the company no longer needed to flag cutblock boundaries with ribbons.

“Prior to the approval of the current process, we would have had to hang ribbons everywhere in the block,” Morgan said. “We can use highly accurate digital maps and modern GNSS technology to ID these same features.”

The company equipped its heavy tree harvesting machinery, called feller bunchers, with Op Tracker, a mapping system that is compatible with ArcGIS Online and made by Esri partner Lim Geomatics. Because Op Tracker is built on Esri technology, Morgan can send the FHPs directly from the office to mobile workers in the field. Inside the logging machines, operators use Op Tracker’s mapping interface to navigate while the app simultaneously collects productivity data in the background.

Each machine is also equipped with an Arrow 100 GNSS receiver that the operators use to see their positions in real time in Op Tracker. In the cab, operators just have to glance at a screen to monitor where they are in relation to identified features and associated protection buffers—all without the need for physical ribbons and paper maps.

This real-time navigation system is particularly vital during December and January, when harvesting operations occur 24 hours a day, in two shifts, with very few hours of daylight. Geospatial technology essentially becomes the harvesters’ eyes, guiding them through the darkness.

“The operators know exactly where they are,” Morgan said. “This has increased our productivity quite significantly over the past five years.”

The operators also use this navigation system on other machinery, called skidders, to transport harvested timber to roadside landings, where it’s picked up by trucks and sent to the mill. Increasing efficiency in all phases of the operation is key to Tolko’s success in such a short harvesting season.

“For us to gain the operators’ buy-in initially on all of this technology, we had to show them the increased productivity,” Morgan said. “Now, I don’t think you could take this system away from them.”

Transformed Forestry Operations

Printing enough ribbons to demarcate the current expanse of Tolko’s seasonal harvest would cost hundreds of thousands of dollars per year, according to standard printing estimates. By going digital, Tolko has eliminated this expense.

“Having our boundaries and features mapped digitally is a huge cost savings,” Morgan said. “With the high-accuracy Eos Arrow GNSS and the flexibility of the Esri products, we are now able to take our business to the next level of efficiency.”

Tolko no longer alters natural wildlife environments with flagging, either. And the company’s steadfast commitment to innovation has allowed it to forge new paths in efficient harvesting operations. As the demand for lumber increases, according to industry-standard price tracking, Tolko is right there, surging its production.

What’s more, the company’s quest for innovation persists. Tolko continually interprets analytics from Op Tracker throughout the harvest season. This data helps both Tolko and its contractors identify opportunities for even more improvement. It also provides insight into how to further optimize operations, such as determining which machines are better suited for specific types of timber or terrain.

“All of this technology has helped us maximize our efficiency in the short operating season,” Morgan said. “The upgrade to a geospatially smart system has transformed our forestry operations and opened the door for even more innovation.”