Since 1981, Murfreesboro, Tennessee-based Venture Express (VE) has been a premier freight hauler for the region’s automotive manufacturing industry. The company’s network of terminals, warehouses, and cross-docks allows it to cater to the just-in-time model that modern manufacturing requires. This means that VE receives the materials it ships exactly when they will meet customer demand—no sooner or later.

Because this management strategy requires precise logistics, VE has always emphasized the importance of technology. Having already embraced Electronic Data Interchange automation and solar trailer trackers, company management knew location-based automation was the next step in VE’s technological evolution.

However, VE’s fleet comprises 800 trucks and 3,700 trailers. The movement of these vehicles involves vast amounts of data that need to be organized visually to be useful in managing the company’s operations. VE staff tried various display methods, but all came with processing, speed, and storage compromises. Finally, VE sought a solution that used ArcGIS software to display and analyze this extensive data pool.

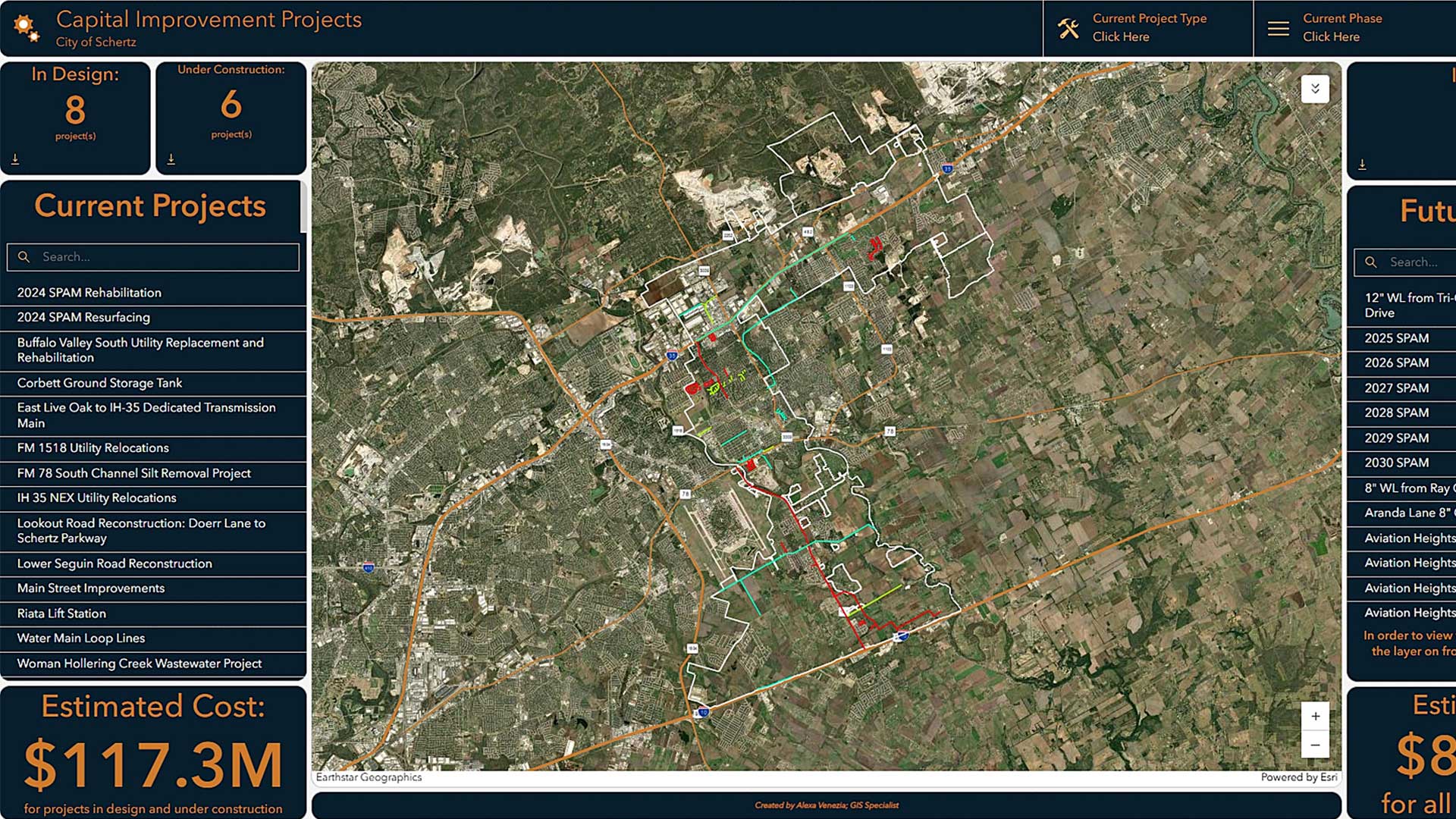

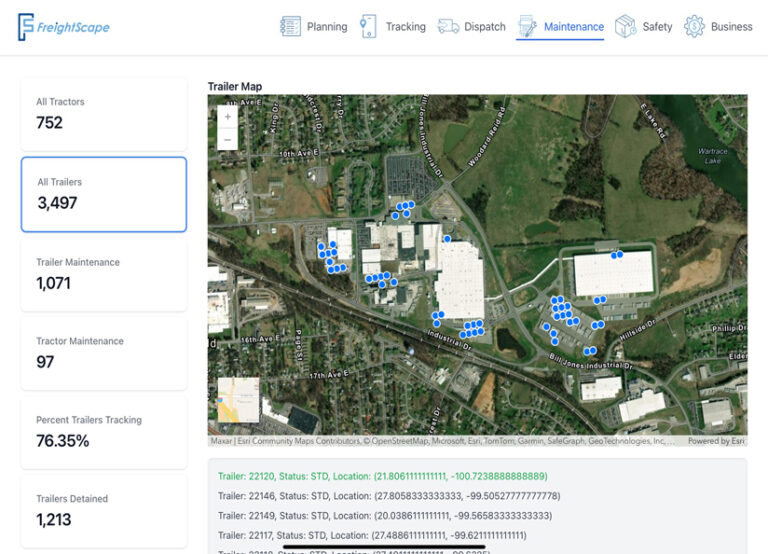

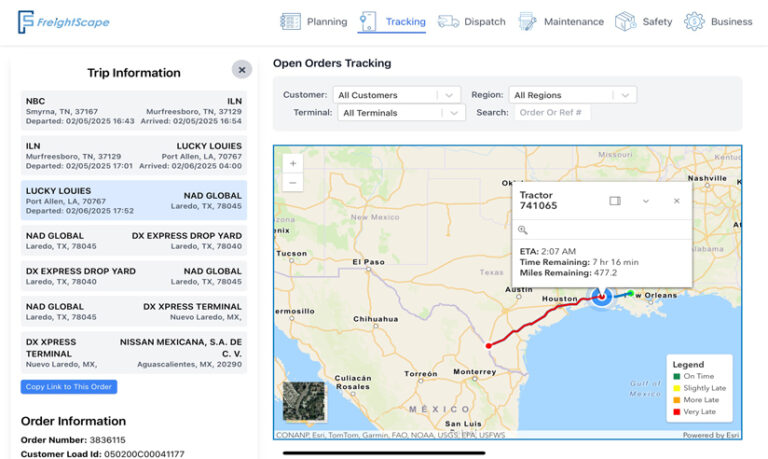

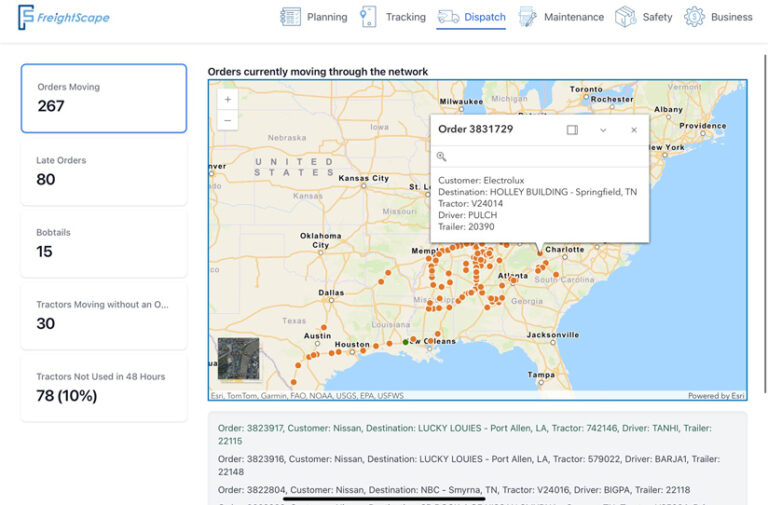

In March 2024, VE teamed up with Esri partner Spatial Freight Solutions to implement and test a new fleet management platform called FreightScape. This web-based program joins disparate data sources—such as the transportation management system, electronic logging devices, trailer locations, and financial data—into a map-based display. Spatial and temporal data are then used to create metrics and automate dispatching. FreightScape has multiple displays to show real-time movements, data trends, and metrics.

From Development to Execution

Before the development of FreightScape, VE used stand-alone applications designed by Freight Solutions developers, who spent nearly a year conceptualizing the different uses and functions of this software suite. The developers’ experience with ArcGIS, however, led them to explore the transportation analysis solver in ArcGIS Network Analyst for VE.

With up to 20,000 location pings a day, ArcGIS Online was the only display choice fast enough to quickly load the location data VE was juggling. In addition, its

truck route layers, open-source data layer (for real-time travel condition updates), and developer SDK made it the right choice for the project. ArcGIS Online was also useful for its cross-platform usability on tablets and mobile devices.

After deciding on the right software, coding and testing took six months. Some existing applications were converted from C# to Next.js, an open-source web development framework, and modified for use in the FreightScape UI.

Developers consolidated existing data in SQL, API, and CSV formats. VE’s terminal locations, domiciles, and customer sites were geocoded and geofenced from existing records.

Data in Action

The goal of FreightScape was to empower every employee, from the CEO down, with the most detailed fleet data available. Because of users’ varying degrees of expertise, the interface prioritizes ease of use. FreightScape’s operation is intuitive, requiring little to no training, and features multiple data layers that are easily accessible. This data fusion makes previously unavailable tracking, dispatching, and analysis capabilities accessible to a wide variety of VE employees who can take advantage of the platform to leverage data to streamline their workflows. Order locations can be viewed in real time on customer-specific links. VE needed to use spatial relationships to reduce human error and noise, thus increasing revenue by using spatial data to match backhauls in real time.

VE data is displayed on various pages, along with metrics derived from real-time relationships. The Tracking page uses ArcGIS REST API to achieve near real-time visibility, updating each truck’s remaining route and current ETA to the destination. Customers can view the status of their orders via a web portal.

The Geofencing page allows for quick updates to the customer database. This virtual business environment tracks daily fleet actions and triggers events—such as automatically closing a completed order or assigning a new one once a truck reaches its actual location.

Other pages include Dispatch (current orders), Safety (driver and safety-related information), Maintenance (asset status), and Business. The Business page shows trends over previous weeks or months, and its customizable key performance indicators (KPIs) can be shared in daily reports.

The software suite also leverages geolocation data in other ways. Specific cross-dock bays can be defined as inbound or outbound to analyze operational efficiency and throughput. A recruiting module examines local order volume and overall network flow to determine where drivers are needed most. Asset utilization metrics identify poorly managed sectors and provide a means to gauge improvements.

Since its launch, FreightScape has reduced manual dispatching by automating order assignments through geofencing, saving dispatchers hours each day and cutting down on costly routing errors. Trailer utilization has improved thanks to spatial backhaul matching, which has translated into fewer empty miles and lower fuel costs. Real-time visibility has allowed customers to proactively plan production schedules, reducing delays and improving service satisfaction. Internally, VE has been able to identify underused assets, rebalance its driver network, and forecast staffing needs more accurately. Together, these improvements have lowered operating costs and increased revenue opportunities.

All of this adds up to a tool that has saved time and money by transforming raw fleet data into actionable business intelligence, ensuring that everything ends up where it needs to go, exactly when it needs to be there.

Although the program originated as a tool for transportation companies, original equipment manufacturers—which require increased supply chain visibility—have also shown significant interest in adopting FreightScape. The modular design lets customers implement only the components relevant to their operation. With “track and trace” and “visibility” among the industry’s current buzzwords, a platform like this has never been so valuable across multiple industries.