Like many city governments around the globe, the City of Stuttgart in Germany is investing in more smart infrastructure with its Smart City Stuttgart project—which means prioritizing sustainability, energy efficiency, and mobility in current and future infrastructure initiatives.

As part of this plan, Stuttgart aims to improve its system of record for urban planning by having a realistic 3D city model created every two years. Not only does this process involve intricate flight planning to obtain aerial imagery, but it also entails acquiring images, conducting photogrammetric processing, and generating final outputs to aid the City of Stuttgart and its stakeholders in supporting urban initiatives.

Enter GeoFly GmbH, an aerial mapping company for the European market. GeoFly uses airplanes to acquire aerial imagery with nadir, oblique, and thermal camera systems for city- and country-wide reality mapping, which can even be further supported by airborne lidar data. GeoFly uses five airplanes overall—including three Diamondcraft DA62 MPPs—to obtain this imagery.

The type of imagery GeoFly captures has historically been used to produce digital surface model (DSM) and True Ortho outputs—meaning imagery corrected for distortions caused by terrain relief. But with increasing efficiency of oblique camera systems, the demand for 3D meshes has grown in recent years, including in Stuttgart.

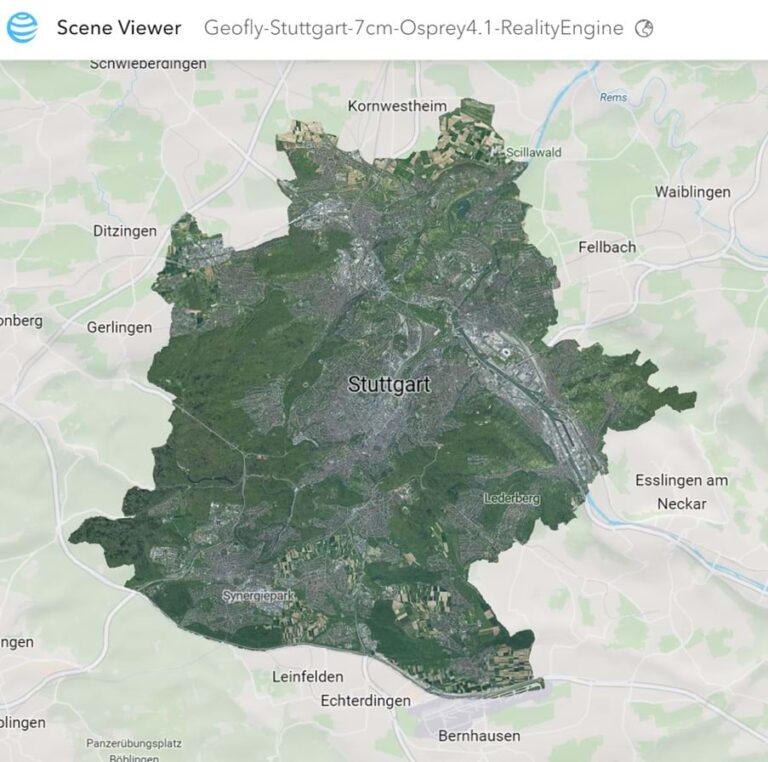

In 2023, GeoFly took to the skies to obtain the necessary aerial imagery of the city of Stuttgart. This imagery was then processed with ArcGIS Reality Studio to create a realistic, comprehensive 3D mesh, a vital tool for building an even smarter city.

It’s Flying Time!

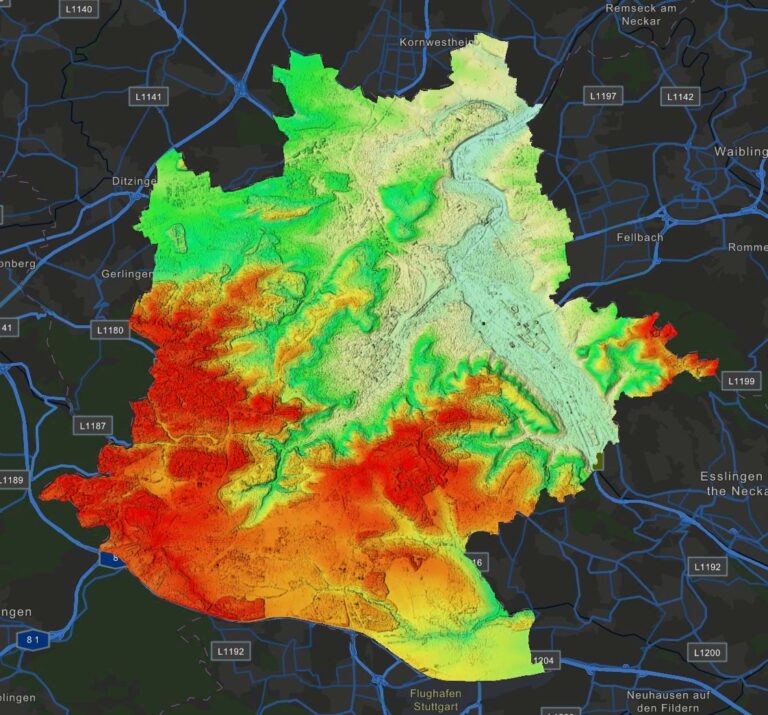

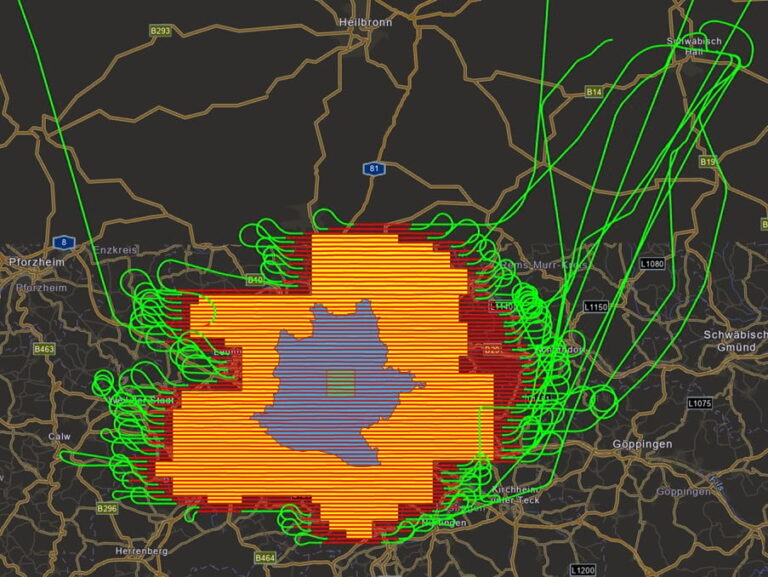

The process of flight planning and aerial image acquisition is different for every city, and several aspects must be considered: ground sampling distance (GSD) and image overlap, for instance, are essential planning components. For Cities with basin-like topography such as Stuttgart, the calculation of the consistent flight height needs to consider the longest distance to ground to guarantee that the maximum GSD is not exceeded, while maintaining the required overlap for all images. In this case, images were acquired at 7 cm GSD, with an additional dataset at 4 cm GSD for the city center.

GeoFly used a Vexcel Osprey 4.1 sensor, which was mounted to one of the Diamondcraft DA62 MPP airplanes. The sensor uses advanced technology to compensate for fast motion during image acquisition. Compared to similar aircraft models, the DA62 has particularly low fuel consumption. In addition, the DA62 uses jet fuel instead of the traditional leaded aviation gasoline. Both factors contribute less to the carbon footprint while still offering economic benefits.

These environmental and economical savings become especially valuable considering GeoFly’s 1300 hours of flying every year, which adds up to 1.8 million kilometers (about 1.2 million miles) flown—meaning that GeoFly covers a distance equivalent to the circumference of the earth almost 45 times a year. Over the last five years, this adds up to an image coverage of 3.5 million square kilometers (about 1.35 million square miles), an area of 10 times the size of Germany, or one-third of the size of the United States.

For the City of Stuttgart project, 69,760 images were acquired, amounting to a whopping 40 terabytes of data and roughly 12.5 terapixels. The nadir images (perpendicular to the earth’s surface) of the larger project area alone cover 1,152 square kilometers (about 445 square miles), amounting to 2330 kilometers (about 1,448 miles) flown and 12.5 hours of flying on four different flying days. The number of flying days—and therefore the vast amount of data collected—reflects the need for optimal weather and illumination conditions.

Data in Action

Once the data capture was finished, it was time for photogrammetric processing. Esri’s ArcGIS Reality Studio was used to perform the image alignment and the processing of DSM, True Ortho, point cloud, and 3D mesh of the complete dataset.

The alignment of the large area included one individual capture session for each of the four flying days. Treating the flying days as individual capture sessions allows consideration of lever arm and boresight misalignments as well as individual camera calibration sets. This alignment process included the measurement of 23 ground control and check points, which can be a time-consuming process. ArcGIS Reality Studio can perform fast control point measurements. Geometric re-projection and image content are used to semi-automatically find the respective features in each relevant image.

“The function for automatic control point measurement is fantastic,” said Susann Nitzsche, head of data production at GeoFly. “I have never experienced it in this quality and implementation before.”

Moreover, ArcGIS Reality Studio offers a variety of easy-to-use quality assurance tools and features for actions such as measuring manual tie points, check points, and ground control points.

The next challenge after completing the alignment process was to generate the photogrammetric products quickly. While the DSM and True Ortho imagery was processed on GeoFly’s office cluster, the Reality Engine was used to process the 3D mesh in the cloud.

“The software looks really good, and the handling is great,” said Aicke Damrau, GeoFly’s managing director. “The quality of the mesh texture exceeds our expectations, even challenging areas such as facades are displayed cleanly.”

Martin Grünheid and Benjamin Vogel, from the City Survey Office of Stuttgart, published the results in their geoinformation system. With an internally shared web scene, other city offices can now use this data for multiple purposes, such as measuring or visualizing shadow gradient, or applications like solar potential analysis.

“We are very satisfied with the quality of the mesh,” said Vogel. “The building edges are reconstructed very sharply.”

For some city planning projects, the City Survey Office shares publicly available web scenes that incorporate a 3D mesh and building proposals from various architects. This inclusive approach allows city inhabitants to actively participate in the decision-making process for the city’s development. The high-resolution 3D mesh of the city center is part of a funding project for mobility and environment, where it is used as a catalyst for other projects such as real-time sensor data integration into a digital twin. There is also a future proposal to combine the 3D mesh with georeferenced historical images. In this scenario, the 3D mesh serves as a photo-realistic, easy-to-navigate layer and allows the user to virtually walk through the city, visualizing historical images for specific locations.