About DB Systel and the TracE venture

DB Systel GmbH, headquartered in Frankfurt am Main, is a wholly owned subsidiary of Deutsche Bahn AG and is a driver of digitalization for all Deutsche Bahn’s group companies. Founded in 2000, DB Systel operates across 13 locations in Germany and employs over 7,000 people from 98 countries. It combines in-depth IT expertise with technical railway know-how to successfully support all partners in the group in their digital transformation. As a digital technology and innovation partner in the information technology industry, DB Systel creates a powerful IT foundation for data-driven decisions throughout the group.

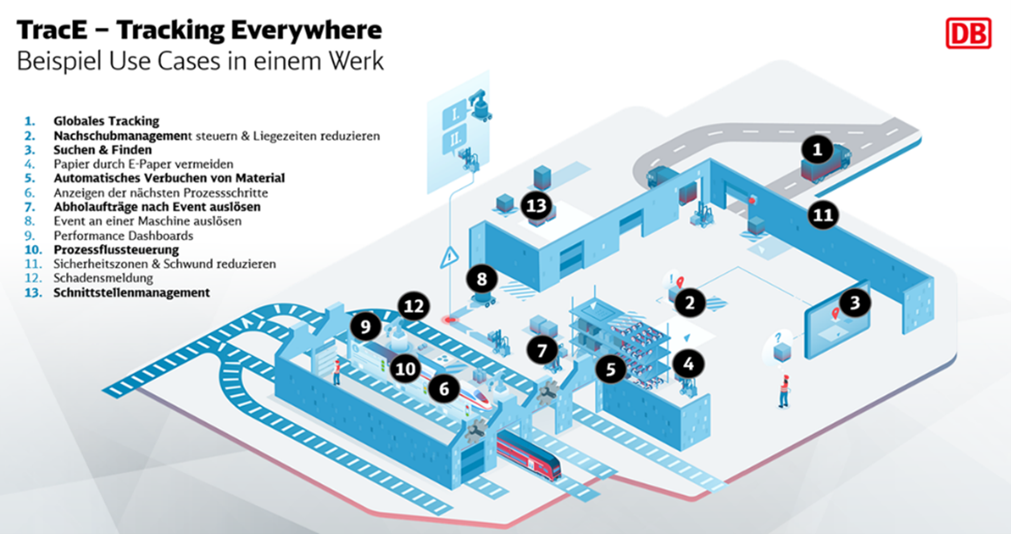

The TracE (“Tracking Everywhere”) Venture is part of DB Systel’s Innovation & Ventures unit and focuses on location services.

With over 30,000 kilometers of route network, around 5,400 stations, and numerous vehicles throughout Germany, Deutsche Bahn produces location-based data every day, ranging from the company’s plants to passenger travel and freight transport. Due to its many physical assets, Deutsche Bahn is one of the largest producers of location-based data in Germany.

The Challenge

In a large corporation like Deutsche Bahn, it is crucial to keep track of all assets. Effective monitoring depends on a comprehensive database and the right technology. Across the organization, various business areas and projects use geographic information system (GIS) technology, generating location data in the process. To build a clean, group-wide database, existing inventory records must be harmonized and enriched with additional information. A central challenge is to collect the data where it is generated—meaning to capture it directly at the source, such as factories or production areas, at the moment it’s created. This ensures the data is accurate, current, and usable across the organization. To support this, Deutsche Bahn is developing a new location data infrastructure to precisely record and utilize information within buildings.

The Solution

The TracE team brings together existing solutions and data streams in a platform that is essentially based on ArcGIS Enterprise and combines the data with TracE’s solutions. TracE uses GIS in combination with positioning technology in three areas: asset tracking, passenger tracking and navigation, and vehicle tracking.

Location Intelligence in Practice: Asset Tracking in DB Plants

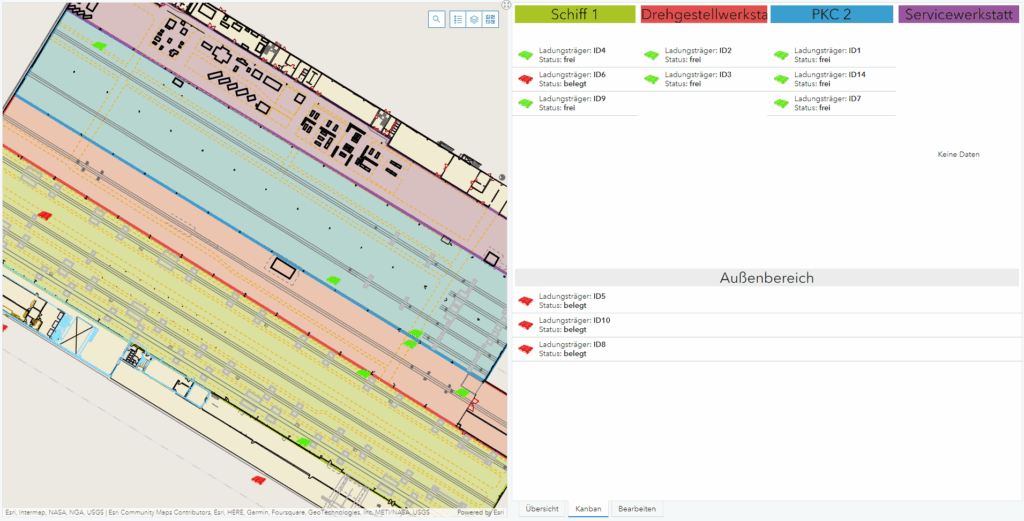

Asset tracking is mainly used in the plants where trains are maintained and components (e.g., masts, switches, or superstructure supports) are built. Vehicle maintenance plants and workshops are large-scale and complex facilities, some of which work with bulky spare parts. At the same time, storage space is sometimes limited, and many processes are interlinked. Real-time data plays a key role in bringing relevant information to the decision-makers’ screens and optimizing processes inside and outside the plants.

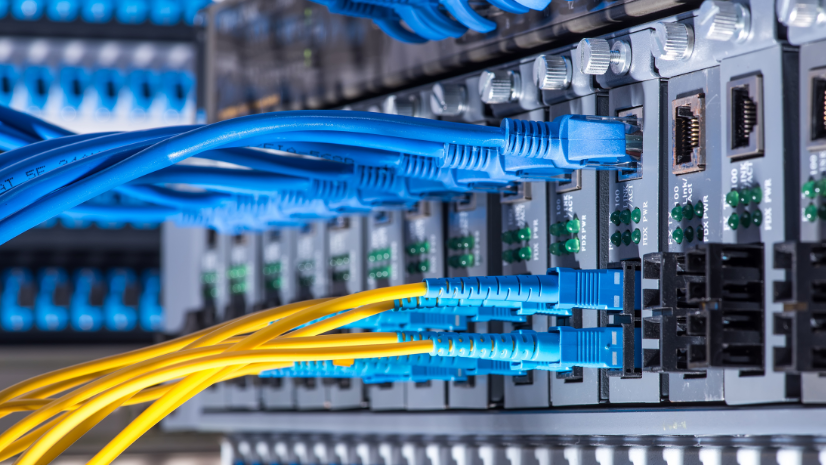

Tags, also known as Bluetooth Low Energy (BLE) beacons, are used to intelligently track relevant assets. At the lighthouse plant in Nuremberg, the interior is equipped with about 200 antennas. With the help of these antennas, the assets can be located. In the factory, the data flows together on an edge device, which in turn transmits the collected information to ArcGIS Enterprise.

The solution is implemented using ArcGIS GeoEvent Server, where the processed data is written into a feature service. Information from the company’s SAP system about the job status or other parameters further enriches the process. This means that the orders, which are initially only available in the control systems, can be placed on a map. Along with shortening turnaround times, this also makes work easier for employees, as individual parts can be located much more quickly.

Intelligently Coordinate Assets

Location data also plays an important role when working on large construction sites and coordinating assets. The DB plant in Witten produces large spare parts, such as switches and rails, that have to be delivered to other plants or construction sites on time. By continuously tracking the position of the large components via GPS trackers, it is possible to map when spare parts are expected to arrive at their destinations over the long term.

By processing this type of real-time data through the ArcGIS Enterprise platform, processes can be reproduced in a very timely manner and decisions can be made based on them.

The Benefits

The long-term collection of a wide range of data means that more than just the current situation can be mapped. Recurring patterns also enable forecasting, which in turn helps identify and eliminate bottlenecks and capacity problems at an early stage. In addition to global asset tracking, GIS and location services provide holistic support for processes in a plant. Waiting, mooring, and turnaround times are shortened, assets are found more quickly; and processes are made more efficient. Various interfaces can be quickly connected via GeoEvent Server—regardless of the intervals at which the data is generated.

Esri Technology in Action

- ArcGIS Enterprise: Data Consolidation, Solution Delivery

- ArcGIS GeoEvent Server: Real-time monitoring of assets, interface connection

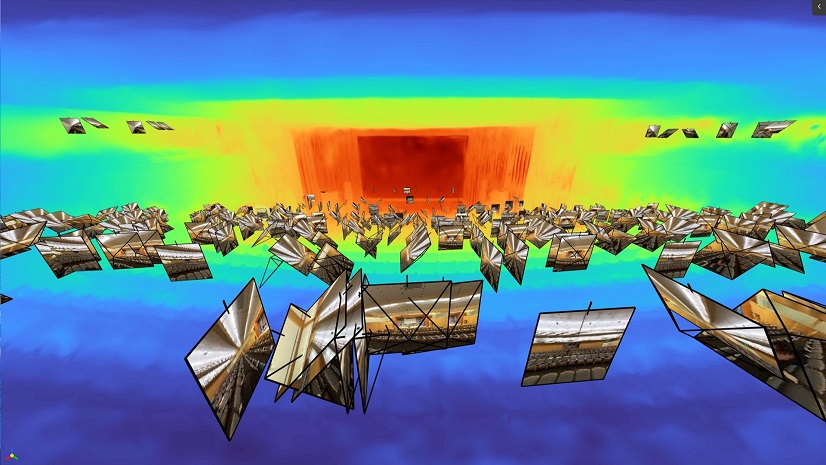

The Path to the Future—The Connected Factory Digital Twin

The Connected Factory Digital Twin is to be developed and established on the basis of the existing technologies, the developed platform, and the products based on it. For its implementation, ArcGIS GeoEvent Server forms the central interface between various systems. In the Connected Factory Digital Twin, data from other projects and participants can be merged into a central digital twin in the long term—for example, machine data and data from process control systems.

By combining this with indoor positioning technology and ArcGIS Routing service, stakeholders can be provided with ways and tools to work more efficiently and safely in the future.

Linking location information across different areas creates new, profitable insights. In order to expand location intelligence, the connection of further live data is planned. The integration of 3D BIM models into the company’s GIS also opens up potential for the future—on the way to the Connected Factory Digital Twin.