A Customer Spotlight Story

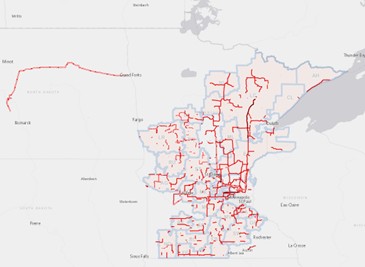

Great River Energy, Maple Grove, Minnesota, is a not-for-profit wholesale electric power cooperative that provides electricity to member-owner distribution cooperatives, serving more than 1.7 million member-consumers. Great River Energy has 5,100 miles of high-voltage transmission lines. The organization is on track to meet Minnesota’s goal to reduce carbon dioxide emissions 80% from 2005 levels, more than 25 years before the 2050 target.

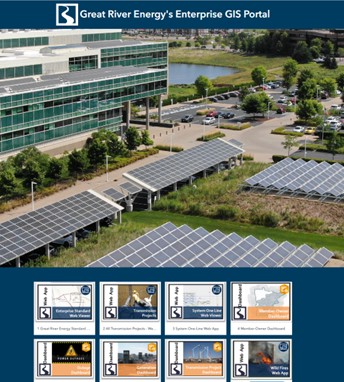

Great River Energy has utilized Geographic Information Systems (GIS) to improve its operational efficiency. This technology enables the analysis and visualization of data related to the transmission network, facilitating better decision-making, streamlined maintenance operations, and improved response times in emergencies.

CHALLENGE

Paper-based, manual asset inspection and maintenance processes hindered Great River Energy’s operational and maintenance efficiency of its extensive transmission systems. These paper-based and dual-entry methods were time-consuming and error-prone. Field crews manually documented issues, took photos, and office staff interpreted and entered data into Maximo, its asset and work management system. This caused delays in maintenance scheduling and prioritization. The lack of spatial data hindered task optimization, resulting in a backlog of maintenance work order resource allocation and potential reliability concerns.

SOLUTION

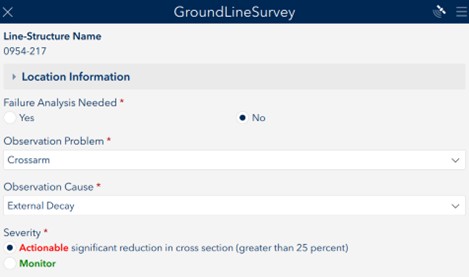

Great River Energy undertook a project to integrate GIS data with Maximo, streamlining data collection, improving accuracy, and enhancing decision-making. It shifted from paper-based processes to digital data collection using ArcGIS Survey123 and ArcGIS Field Maps. Mobile crews directly captured detailed information, photos, and severity levels in the field. This data was then fed into Maximo, reducing the need for manual entry and errors.

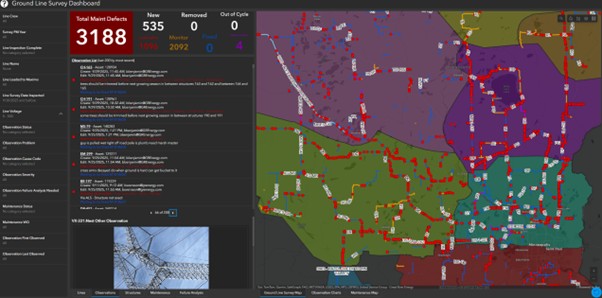

“All crews with iPads in the field were a game changer; they could easily navigate the corridor, look and review previously collected defects, and fix nearby issues during outages. The dashboards give us detailed information from tracking the survey process completion to optimizing maintenance work.” Jonathon McGuire, Supervising Manager, Transmission Construction & Maintenance

The synchronization of GIS and Maximo data enabled improved visualization and prioritization of maintenance tasks and enhanced situational awareness during emergencies. An ETL (extract, tranform, load) process automated the transfer of data from GIS to Maximo. Upon completing a field survey, the ETL process transferred the collected data into Maximo’s condition monitoring system for additional analysis and assessment of asset health used in replacement ranking.

Another improvement solution involved using ArcGIS Hub to enhance coordination with multiple contractors for data collection. This is heavily used on a new regional transmission projects. These new transmission lines are designed to enhance the reliability and resiliency of the electrical transmission system in Minnesota and surrounding regions. This hub site was crucial for ensuring all parties had access to the most up-to-date information, facilitating smoother project execution and compliance.

“The benefits of this integration are clear, and Great River Energy is well-positioned to continue leveraging advanced technologies to drive further improvements in asset management and compliance.” Andrew Schmidt, Project Manager – GIS at Great River Energy

RESULTS

Integrating GIS with Maximo has transformed Great River Energy’s transmission system management. Digital data collection now replaces manual entry, allowing field crews to submit real-time data and keeping Maximo accurate and current. This enhances asset management efficiency. With GIS-Maximo data integration, Great River Energy can prioritize and group maintenance spatially by issue, severity, and criticality into work packages. The system organizes defects by line and work territory, generating a single corrective work order per work group. Managers and leadworkers review captured defects and package work, ensuring that the most critical issues are addressed first, boosting system reliability and reducing work order management.

“Service territory shops can easily assist other shops using GIS mobile applications. This helps ensure that our assets are inspected annually while maintenance activities and project work get done.” Timothy Balbach, Supervising Manager, Transmission Construction & Maintenance

The automated data transfer and streamlined maintenance processes have resulted in substantial labor savings. Field crews can focus on more critical tasks, and the administrative burden of managing data has been significantly reduced. Over time, this has resulted in cost savings and enhanced operational efficiency. The data integration has also improved Great River Energy’s ability to comply with regulatory requirements and generate accurate reports. The synchronized data between GIS and Maximo ensures that all asset information is consistent and up to date, making it easier to meet compliance standards and provide detailed reports to stakeholders.

BENEFITS

By improving the accuracy and timeliness of data, Great River Energy can better identify and address potential issues before they become critical. This proactive approach has significantly enhanced the transmission system’s reliability, reducing the frequency and duration of outages. The accurate data and visualizations GIS provides enable Great River Energy to make more informed decisions. Field crews and management can quickly assess the condition of assets and prioritize maintenance tasks, leading to more efficient and effective operations.

The reduction in manual data entry and the optimization of maintenance processes have resulted in significant cost savings. Great River Energy can allocate resources more strategically, focusing on high-priority tasks and reducing unnecessary expenditures.

Moving from the paper-based system to the evolving mobile GIS process has given us many operational efficiencies, such as simplifying the collection process, reducing and clarifying cause codes, and field prioritization of issues from actionable or needing to be fixed to monitor has resulted in 450 hours saved and 77% fewer work orders generated.” Matthew Reule, Manager, Transmission Construction & Maintenance

The collaborative hub site for the Northland Reliability Project has fostered better communication and coordination among contractors and internal teams. This has led to smoother project execution and higher compliance with project standards.

NEXT STEPS

Great River Energy is considering greater use of advanced technologies, such as drones and augmented reality (AR), for data collection. Drones can perform aerial line surveys and efficiently capture detailed images and data. Great River Energy is looking into ArcGIS QuickCapture to enhance the baseline capabilities beyond visual line-of-sight drones, allowing them to inspect difficult transmission line corridors quickly.

AR can enhance field operations by overlaying critical information in the real-world environment, improving situational awareness and decision-making. Drones will aid aerial line surveys, capturing high-resolution images and data that can be quickly analyzed and fed into GIS. AR will overlay critical information in the real world, enhancing field operations and situational awareness.

Great River Energy will expand the use of ArcGIS Hub to other projects and initiatives. This will ensure that all contractors and internal teams can access the most up-to-date data, facilitating better collaboration and compliance.

Great River Energy is exploring additional use cases for the integrated GIS and Maximo systems, such as predictive maintenance and asset lifecycle management. These use cases will further enhance the company’s ability to manage its assets effectively, ensuring long-term reliability and performance.

“Integrating GIS data with Maximo has been transformational for Great River Energy. By addressing the challenges of manual and paper-based processes, we have improved data accuracy, enhanced decision-making, and optimized maintenance and emergency response operations at Great River Energy.” Jeff Grussing, Manager of GIS Development and Technology at Great River Energy.