We make the world's most powerful GIS software

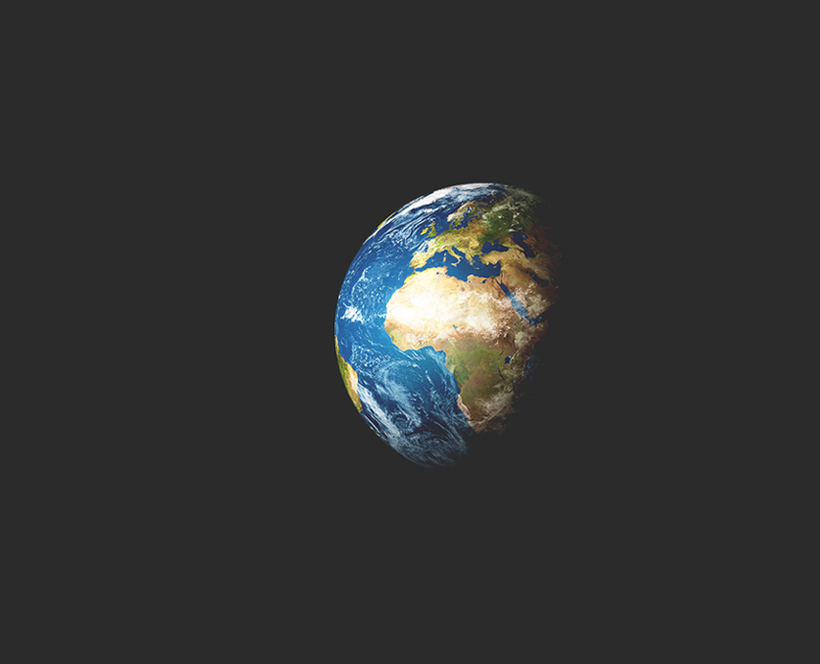

Esri is the global market leader in geographic information system (GIS) software, location intelligence, and mapping.

Since 1969, we have supported customers with geographic science and geospatial analytics, what we call The Science of Where.

We take a geographic approach to problem-solving, brought to life by modern, enterprise-grade GIS technology. We are committed to using science and technology to build a sustainable world.