The Walk Bridge in Norwalk, Connecticut, carries four tracks of the Metro-North Railroad line over the Norwalk River. But this swing bridge, which currently swivels to accommodate boat traffic, was built in 1896 and has outlasted its intended life-span, according to the Connecticut Department of Transportation (CTDOT). It is being replaced by a vertical lift bridge that will ascend and descend to let ships pass through. And the entire bridge replacement project will be done while maintaining railroad traffic over the existing bridge—a complex undertaking, to say the least.

Infrastructure solutions firm and Esri partner HNTB has been working on the replacement design for Walk Bridge for several years. One of the challenges the team has faced is connecting disparate data and systems during the design process. After becoming an early adopter of Esri’s new ArcGIS GeoBIM on another project, leaders at HNTB realized that the solution could be used to quickly connect geospatial and building information modeling (BIM) data on the Walk Bridge project. Not only that, but by incorporating ArcGIS Velocity to monitor live sensor data on the existing bridge during key parts of the construction process, the team recognized that ArcGIS GeoBIM could be useful well beyond the design and construction phases of the project. It could help with operations and maintenance on the new bridge as well.

“ArcGIS GeoBIM isn’t just a design tool; it’s something that owners and operators need to be thinking about using as part of their digital twin framework,” said Darin Welch, associate vice president for geospatial and virtual engagement solutions at HNTB’s Technology Solutions Center. “If they see the value in monitoring the tilt, movement, and temperature of the existing bridge during construction, then it’s a logical next step to use this technology to monitor bridge conditions during normal operations.”

Integrating Different Tools and Systems for a Major Airport Project

For HNTB, bridge work is its bread and butter—and has been since the company was founded more than 100 years ago. But the transportation-focused consulting firm has worked on other major projects as well, including a multibillion-dollar passenger terminal upgrade at one of the largest international airports in the United States.

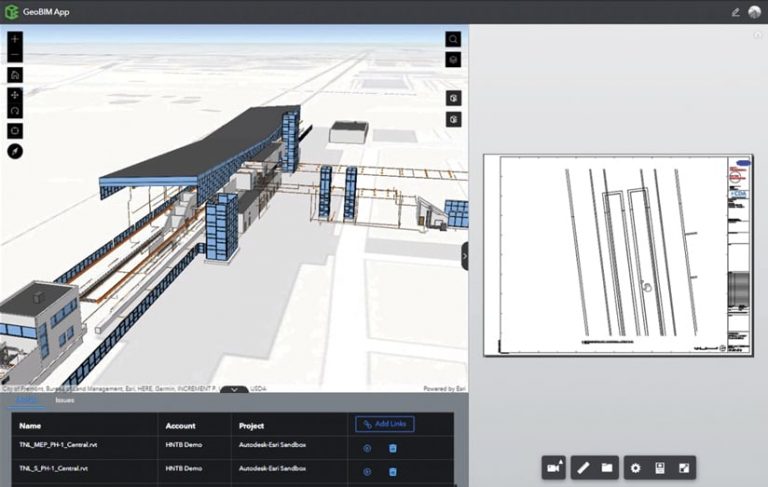

The airport expansion and redevelopment project consists of adding new concourses; replacing and expanding airport gates; and developing a new central tunnel system to convey utilities, baggage, and passengers to satellite concourses. To understand how each of its design proposals would impact the airport’s surrounding infrastructure, the team at HNTB took a model-first approach to the project and built a digital twin—a 3D model that allows stakeholders to visualize real-world outcomes and collaborate more easily. This was the first time HNTB team members had employed ArcGIS GeoBIM to produce a digital twin and ensure that their infrastructure designs also supported location-based intelligence.

ArcGIS GeoBIM, a software as a service (SaaS) solution, integrates project information from Autodesk BIM 360—part of the Autodesk Construction Cloud that connects data across a project’s life cycle, from design to hand over—and blends it with geospatial data from ArcGIS. For the airport project, Welch said he knew that integrating different tools and systems was going to be important, so the opportunity to explore ArcGIS GeoBIM came at the perfect time.

“We saw ArcGIS GeoBIM as a great opportunity to help visualize [design variations] because the subsurface utilities were in both CAD [computer-aided design] and GIS formats,” said Welch. “And because of the model-first design approach of the tunnel and how that connects to the new concourse and terminals, we needed a way for the team to better visualize changes and conflicts with the 3D subsurface utilities…like the air duct system.”

One of the big advantages to using ArcGIS GeoBIM is that it relieves the team at HNTB of having to translate various types of data into formats that can be used in one program or another.

“You’re losing efficiency in the need to constantly translate those things,” said Welch. “And you risk accuracy if you’re not using the correct data or [if] somebody is using something that was translated and didn’t realize it should have been retranslated.”

Thanks to the recent partnership between Autodesk and Esri, ArcGIS GeoBIM works with various Autodesk Construction Cloud products, including Autodesk BIM 360, allowing BIM and GIS data to be used together in collaborative workflows.

“When we first heard about the partnership, it excited us because we could finally integrate the two solutions without having to do continual translation,” said Welch.

Now, for the airport project, the team at HNTB connects ArcGIS GeoBIM users in a web-based environment directly to the project data on Autodesk BIM 360, no matter where the data is coming from. Stakeholders can access project materials, like live working files and the latest maps, in a single location, which enables them to understand how the most recent designs for the airport’s underground tunnel would affect things like utilities.

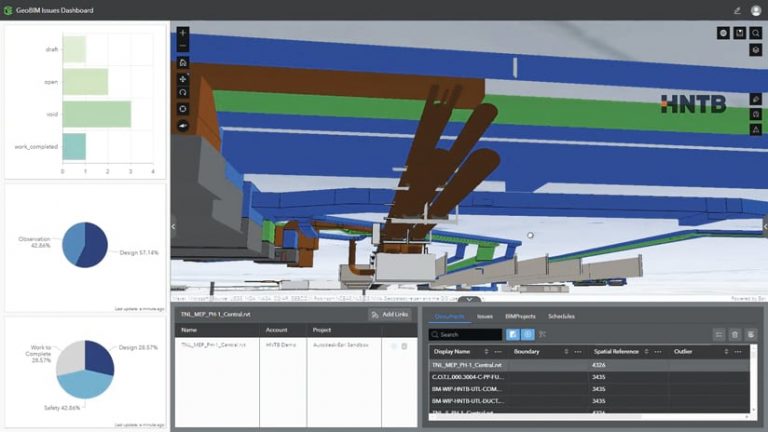

According to Welch, ArcGIS GeoBIM also introduces the concept of a data cooperative that gives users confidence that they are accessing the most accurate information regardless of system or source.

“[We’re] able to see GIS data and 3D civil CAD design, 3D architecture, subsurface GIS 3D utilities, [and more] in a single application that also lets people be notified of conflicts or item markups coming from the field,” said Welch. “ArcGIS GeoBIM is like the ultimate aggregator of information. We often find [data] silos in our work, and this solution lets us bring information together into that single interface.”

An Opportunity to Use ArcGIS GeoBIM After Construction

Once team members at HNTB saw how well ArcGIS GeoBIM worked for the airport redevelopment project, they began to explore other ways to employ the technology.

“We started as a movable bridge firm, so we challenged ourselves to consider, is there a bridge design project where we could use ArcGIS GeoBIM?” recalled Welch.

The team also wanted to demonstrate the value of ArcGIS GeoBIM for bridge information modeling, or BrIM—a type of BIM that functions horizontally, for bridges, instead of vertically, for buildings.

“We felt that if we could prove [the value of ArcGIS GeoBIM] for BrIM, it could open the door to other aspects of design engineering that we do,” Welch continued. “If we can prove it on a large scale like an airport, which is almost like a small city, and we can prove it on a smaller-footprint project, like a bridge that still has lots of complexity, we feel like that spans the gap of any design, construction, engineering scenario we would encounter.”

“We’re trying to really modernize our design processes and workflows here at HNTB and take a 3D model-first [BIM] and web-first GIS approach,” added Adam Horn, civil integrated solutions team lead at HNTB. “The lightbulb moment was, holy cow, [ArcGIS GeoBIM] is the realization of web-first and model-first in one application. And we’ve never had that.”

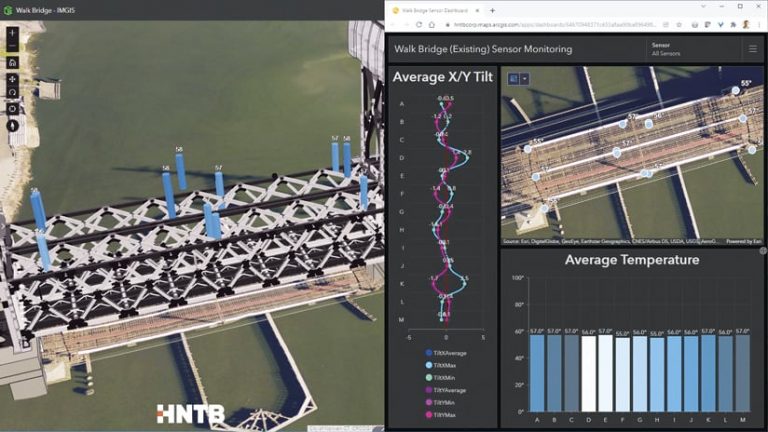

Because the team at HNTB was already modeling Walk Bridge in 3D, using both CAD and GIS file formats, it made sense to start employing ArcGIS GeoBIM on the project. But what’s really innovative—and moving ArcGIS GeoBIM into serious consideration for continued use beyond the design and construction phases—is how HNTB is thinking about incorporating ArcGIS Velocity, which enables users to process and visualize real-time data from sensors, into the solution.

“One of the challenges during construction of the new bridge is going to be monitoring the existing bridge, since [CTDOT] is going to maintain revenue train service on the existing bridge during construction,” Horn explained. “The existing bridge already has sensors installed on it, so what we’re proposing to do with [CTDOT] is to use ArcGIS GeoBIM with Velocity to integrate that live sensor data and monitor the existing bridge during critical construction periods. If there’s any movement on the existing bridge that exceeds the threshold values of baseline activity that we set during ground truthing, that would…stop service immediately.”

Velocity stores historical and current data from the sensors, which not only makes it useful during construction but also worthwhile for CTDOT to employ for normal bridge operations and maintenance.

“When we proposed ArcGIS GeoBIM as the single solution to bring all [the design and construction] data together, it seemed like a no-brainer to incorporate another Esri product that is built to ingest and harvest and manage live sensor data,” said Welch.

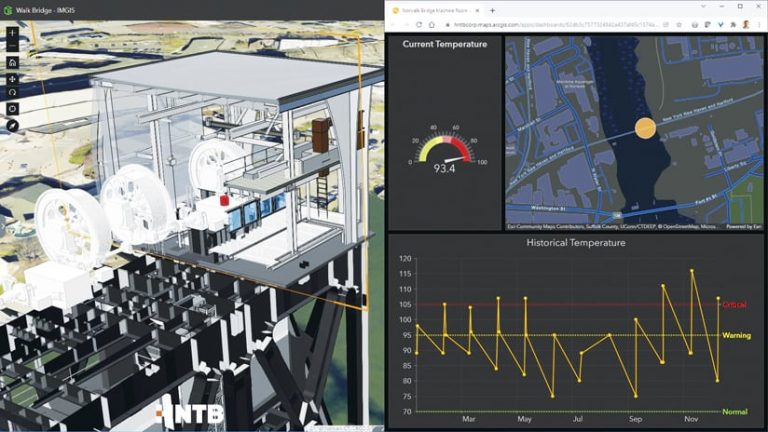

He thinks that ArcGIS GeoBIM and Velocity could ultimately be used together in the new Walk Bridge’s machine rooms, which control the bridge’s ascents and descents.

“Temperature gauges in the machine rooms, for example, cannot exceed a certain threshold,” said Welch. “Because Velocity is the means to share both current and historical information like that and…users can see [all this] from a single place—ArcGIS GeoBIM—it seems like a logical continued integration.”

According to Welch and Horn, team members at CTDOT are already brainstorming ways to use ArcGIS GeoBIM and Velocity to associate their inspection data and full maintenance history with all the different elements of the bridge.

“You don’t have to limit yourself,” said Welch. “We’re trying to show everyone that ArcGIS GeoBIM can be the single location where you make design, construction, operational, and maintenance decisions. It can carry you all the way through all those steps.”