A Customer Spotlight Story

Indonesia’s state electricity company, PLN, manages one of Southeast Asia’s largest and most complex power distribution networks. With more than 89 million customers and 500,000 kilometers of transmission and distribution lines spread across 17,000 islands, inspection and maintenance had long been one of its most resource-intensive operations. Maintaining asset reliability is critical and complex.

Indonesia’s geography poses challenges for PLN’s asset inspections.

CHALLENGE

Keeping such a vast network reliable requires regular inspections. For years, PLN relied on barcodes affixed to poles and substations. Inspectors scanned these labels to record asset data, but the system was cumbersome to use. Labels had to be printed, distributed, and affixed to assets across a challenging geography, then replaced when they were damaged by weather or vandalism. Handheld scanners added to fieldwork burdens, and even when scans were successful, the information was not seamlessly integrated into PLN’s enterprise systems. Reports were uploaded later, sometimes after significant delays, creating opportunities for errors and data loss.

This dependency on barcodes meant inspections were still slow, costly, and prone to inconsistencies. More critically, the system provided limited insight into the true condition of assets. Regulations required inspections every three months in urban and every six months in rural areas, adding pressure to already stretched inspection teams. PLN needed a new model to deliver accuracy, scalability, and long-term efficiency.

SOLUTION

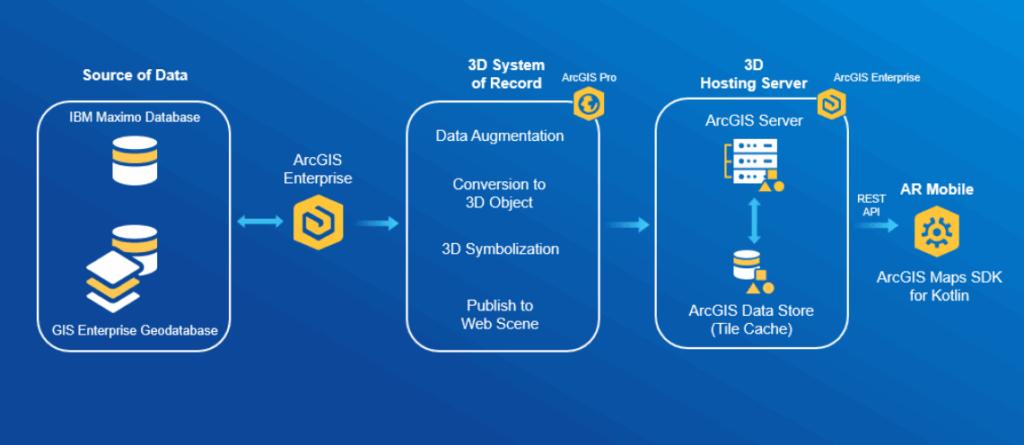

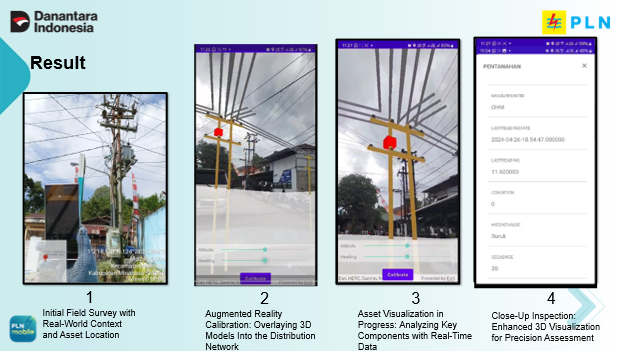

PLN’s breakthrough came with the adoption of ArcGIS, integrated with augmented reality (AR). Instead of relying on physical barcodes, the company created a digital twin of its network. Every pole, line, and substation was represented in ArcGIS, enriched with attributes such as installation year, inspection history, and health rating.

Field crews were equipped with smartphones and tablets running ArcGIS Field Maps. Using AR visualization, inspectors could align their devices with real-world assets and instantly view digital overlays showing asset information. This innovation eliminated the need for physical labels and barcode scanners, as well as the recurring costs of maintaining them.

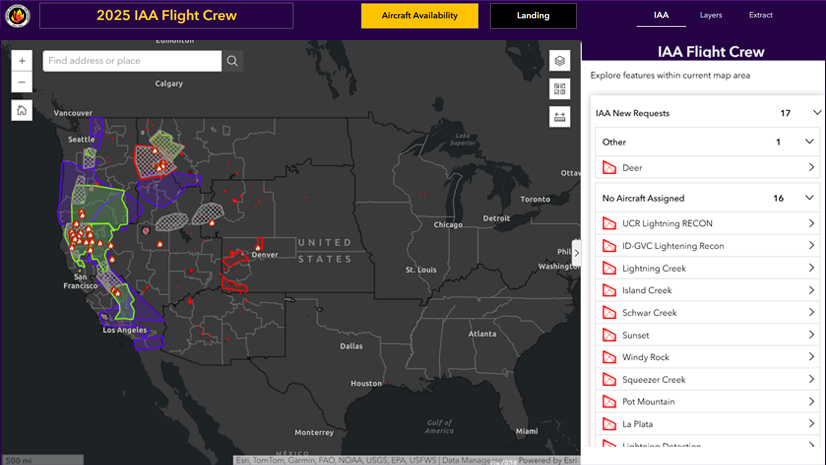

The workflow became seamless. Inspectors navigated to assets using GIS-based maps, then verified them through AR overlays. Inspection checklists were built into the mobile app, ensuring consistency across teams. Data was synchronized automatically with ArcGIS Enterprise and integrated with IBM Maximo, PLN’s asset management platform. Supervisors received results instantly, with condition data displayed on live dashboards for faster analysis.

Another innovation was using ArcGIS Pro to build 3D models of PLN’s infrastructure. Inspectors could virtually visualize underground cables or internal equipment, reducing the need for invasive or hazardous inspections. Training supported adoption, with Esri Indonesia’s solution engineers guiding PLN teams through the cultural and technical shift.

The workflow included AR integration with GIS for real-time visualization, preparation of GIS with asset details, development of a tailored AR application, field testing in real-world environments, and collection of user feedback for iterative improvements.

RESULTS

The shift from barcodes to ArcGIS-driven inspections delivered rapid results.

Inspection times dropped significantly. Crews no longer wasted time locating damaged barcodes or carrying extra devices. Instead, they used one integrated application to capture, verify, and submit inspection data. Inspections that once took days were completed in hours, helping PLN meet its annual target of inspecting over 1,000 kilometers of lines with limited staff.

Accuracy improved as well. By aligning field data directly with GIS assets, PLN eliminated transcription errors and reduced discrepancies. Dashboards made asset conditions visible in real time. Supervisors could immediately identify poor asset condition and prioritize maintenance, reducing outages.

Financial analysis showed the long-term advantage of moving beyond barcodes. Although the ArcGIS-enabled inspections were initially about 23 percent more expensive than barcode-based methods, the cost curve changed after about 600 kilometers of inspections. By eliminating the recurring printing costs and replacing labels, PLN reached break-even within 6 months. From that point forward, inspections became more cost-effective than the barcode system. Safety gains were also important. With AR, inspectors identified hazards before climbing poles or entering substations, lowering accident risks. The reduced reliance on physical tagging also meant fewer close interactions with high-voltage equipment. Clearance around trees was easily uncovered using this innovation.

Augmented reality driven by ArcGIS Pro, visualized in 3D map scenes, was the ah-ha moment for PLN.

BENEFITS

The transition to ArcGIS and AR delivered benefits across PLN’s operations. Inspections became simpler and safer for field crews without barcode scanners or label maintenance. Inspectors could focus on assessing conditions and reporting issues rather than managing equipment or paperwork.

“Esri technology offers many options and is easy for anyone to implement, but the real challenge lies in making the right choices.” – Very Fernando, Technology Expert at PLN.

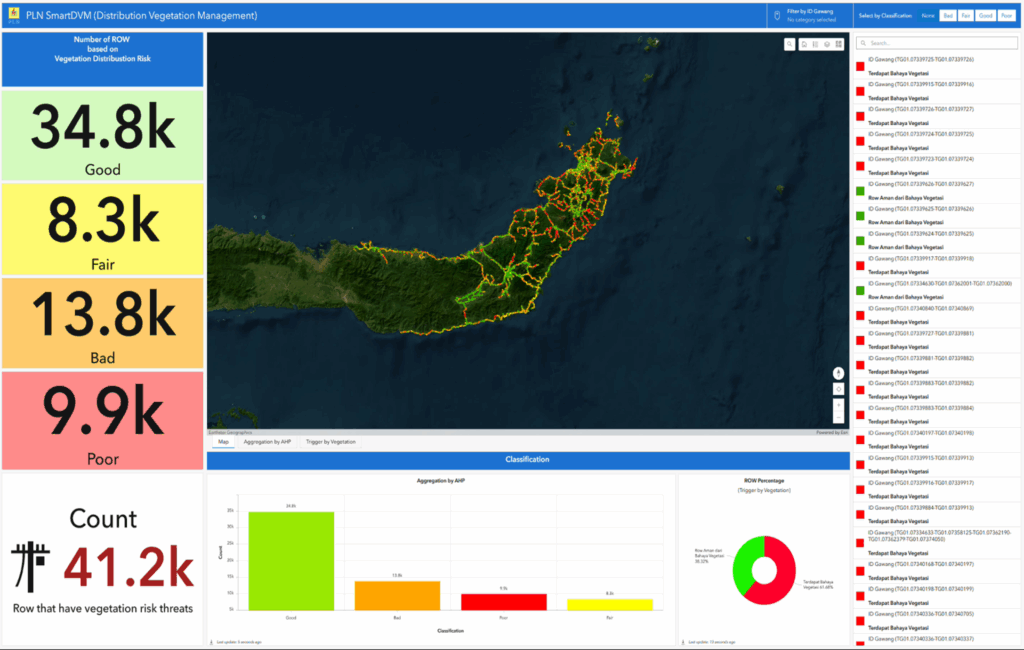

For managers, real-time dashboards built in ArcGIS provided actionable insights. They could monitor inspection progress, identify hotspots, and strategically allocate resources. Planning became proactive rather than reactive, thereby improving the network’s overall reliability.

Customers benefited as well. Faster inspections and earlier defect detection led to fewer service disruptions. By modernizing its workflows, PLN delivered more consistent electricity to households and businesses, supporting economic growth and community wellbeing.

Strategically, the project positioned PLN as a leader in digital transformation within the utility sector. By eliminating barcode dependency and adopting ArcGIS-based inspections, PLN created a scalable model that could evolve into predictive maintenance, IoT integration, and AI-driven analytics.

ArcGIS Dashboards provides transparency, improving accuracy and safety.

PARTNER

Esri Indonesia provided consulting, configuration, and modeling services to PLN and remains a strong partner in PLN’s GIS journey.

NEXT STEPS

PLN views its adoption of ArcGIS as the foundation for a broader digital transformation. Plans include extending inspections to more underground cables and other assets that are traditionally difficult to access. The company is also piloting IoT sensors connected to ArcGIS to provide continuous condition monitoring.

Machine learning models are being developed to analyze inspection data and predict failures before they occur. By combining satellite imagery with ArcGIS, PLN will also improve vegetation management, reducing the risk of encroaching trees. Finally, the roadmap calls for scaling this model across all PLN regions to create a consistent, nationwide inspection standard.

“Managing vegetation means managing reliability, every tree trimmed is a step toward uninterrupted power.” – Irvan Kristianto, Vice President, Distribution and Customer Application.

SUMMARY

Challenge: Manual barcode inspections were slow, costly, and error-prone. Labels had to be printed, replaced, and scanned, but data was often delayed or incomplete.

Solution: PLN replaced barcodes with a digital inspection system built on ArcGIS and AR. Inspectors now use mobile apps to identify assets, record conditions, and sync results instantly.

Results: Inspections are faster and more accurate.

- Real-time dashboards enabled better planning.

- Costs broke even after ~600 km, outperforming barcodes at scale.

- Safety improved through AR visualizations.

Next Steps: Expansion into underground assets, IoT sensors, predictive analytics, and nationwide scaling.