What do construction, hospitality, and lawn care have in common? For one, they’re all industries that are busiest in warmer summer months. They’re also among the target industries of a recently extended heat-related hazard program by the Occupational Safety and Health Administration (OSHA). Under the program, businesses in over 50 industries are responsible for protecting employees from heat-induced hazards.

As extreme-heat events intensify, employers are being tasked with prevention measures like providing shade, water, and rest breaks; monitoring weather forecasts; and training workers on heat safety. By asking one key question, business leaders can focus efforts on high-risk and high-priority work sites. They need to know where hot weather and heat events are happening in relation to their operations—a question they can answer clearly and quickly using geographic information system (GIS) technology.

Heat Events, Maps, and Precision Preparation

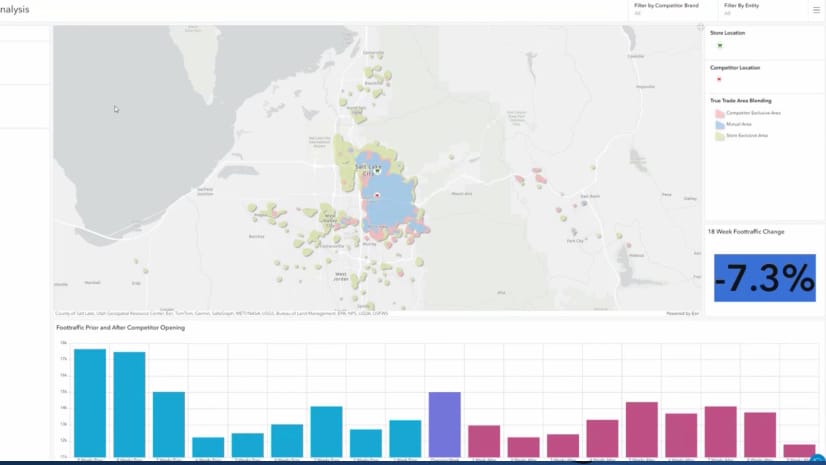

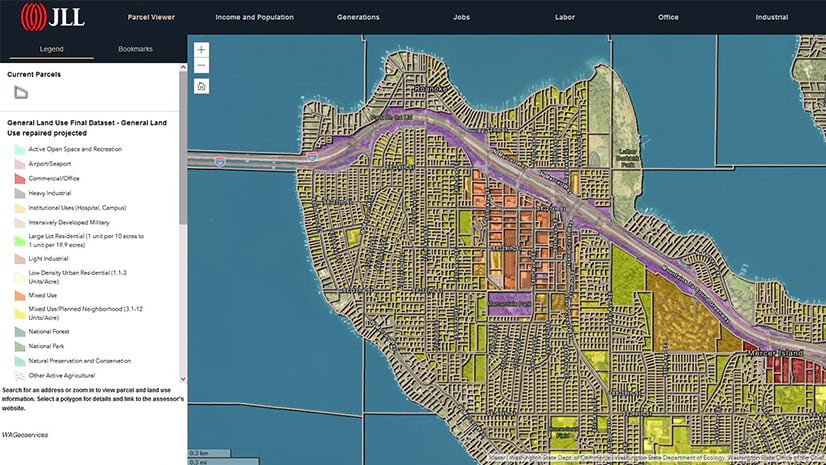

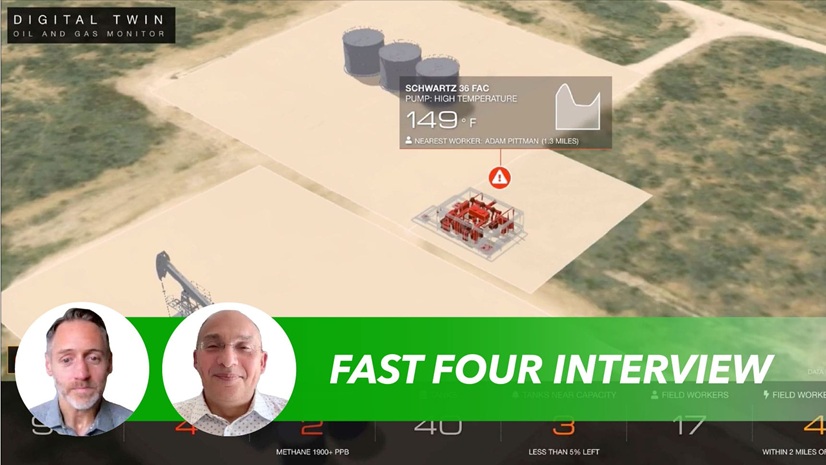

In simplest terms, GIS shows business data—like employee records, jobsite logs, work orders, and project timelines—on a map, revealing which operations are happening where.

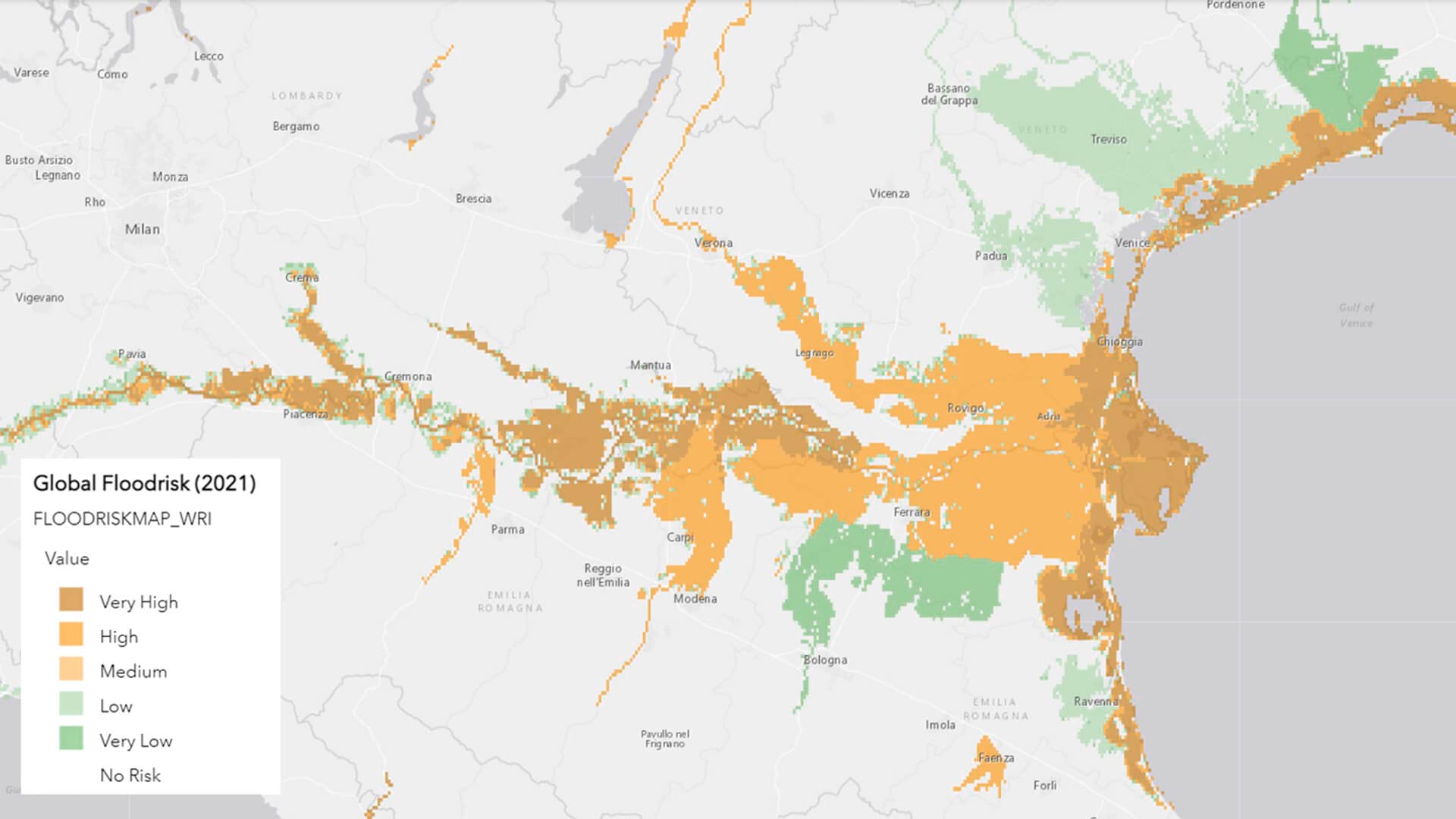

The technology also enriches data with layers of geographic information. These layers show decision-makers who is working at which site, what the weather is like there, whether extreme heat events are likely in that region, and how the surroundings could mitigate or exacerbate heat effects.

This geographic context helps decision-makers and compliance teams apply preventive measures with more intention. For example, businesses can reserve expedited training for their highest-risk facilities while giving other locations more lead time to minimize work delays. Or, instead of investing in new facilities that provide shaded areas and water sources, they could identify nearby infrastructure to repurpose.

Integrating Data Demystifies Compliance Management

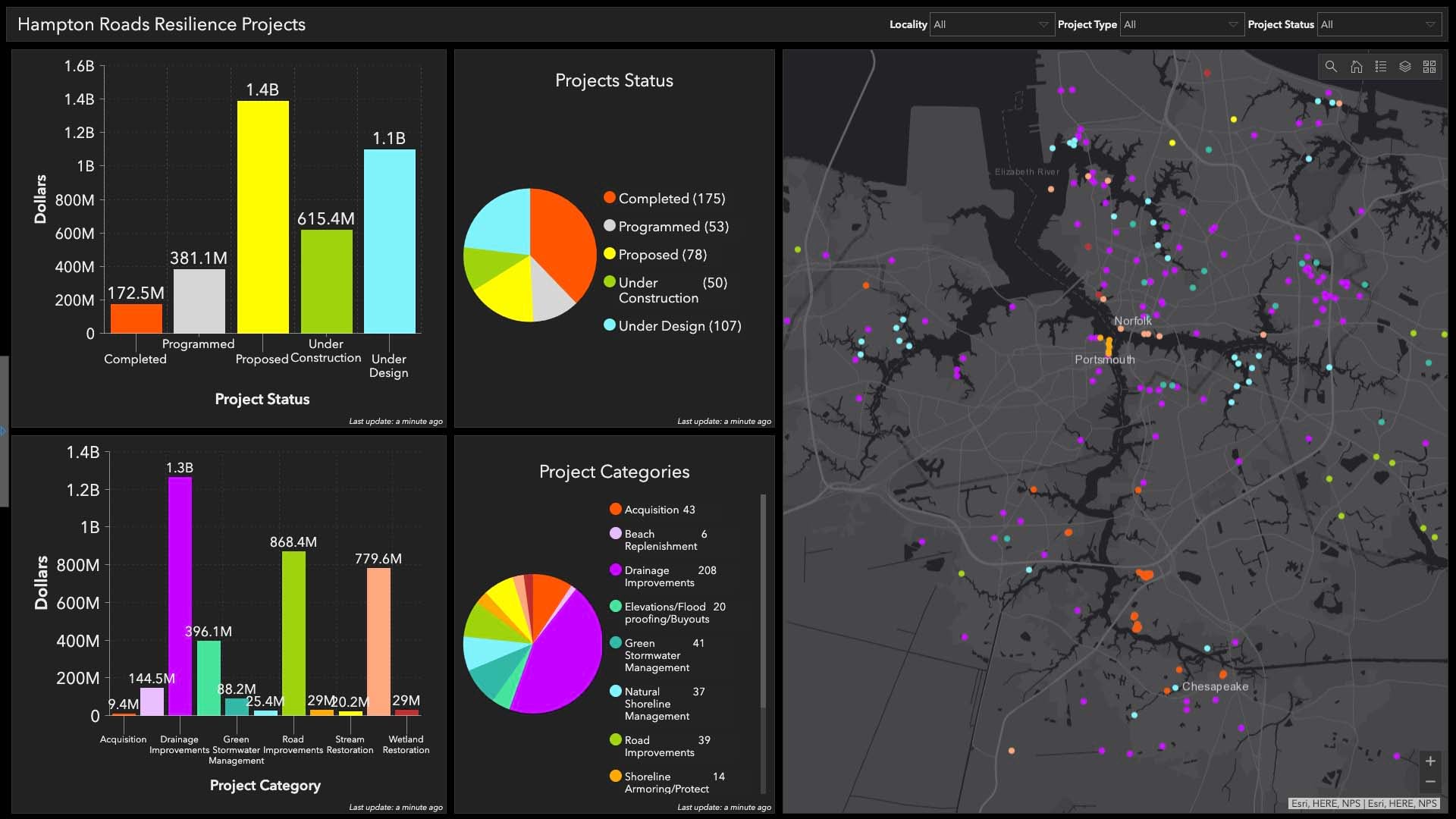

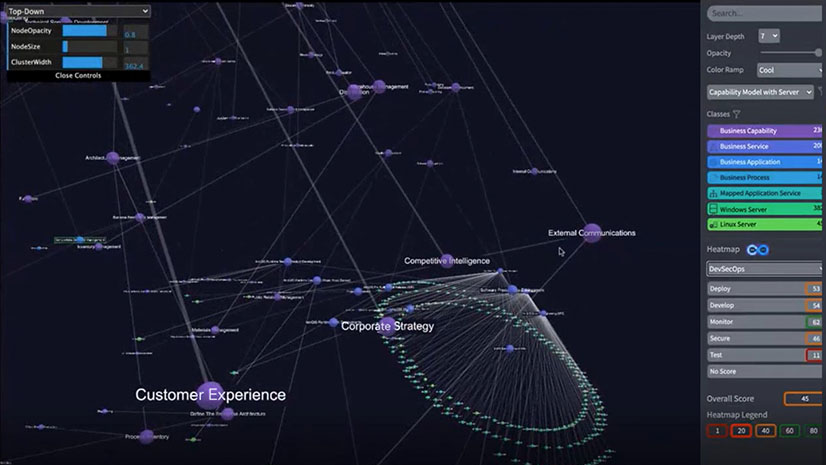

Compliance data is often spread across an organization: Facility management teams may own information about air conditioning maintenance, while employee training records live with human resources. GIS unifies that data while maintaining privacy, giving businesses a centralized view of compliance information across departments and business systems like EAM and ERP.

Instead of sifting through spreadsheets to see whether a facility is compliant, executives and operations managers can use an interactive map. Once they locate a site of interest, they can access more details about its compliance status, safety enhancements, or weather forecast. These map-based reports can also be shared with compliance officers during inspections.

Improving Outcomes Through Smarter Safety

As many industries gear up for their most productive season, now is the time for employers to take steps to prevent heat-related illnesses and ensure safe working environments for employees.

Although OSHA’s future as a regulatory body has come under scrutiny recently, businesses are still beholden to these heat safety standards for now. And compliance aside, companies benefit from taking heat hazards seriously. Safe working conditions prevent productivity loss, reduce employee turnover, and minimize costs for employee health care, according to McKinsey. Companies can compound these benefits if they also use technology like GIS to ensure an efficient rollout of their heat hazard prevention plans.

The Esri Brief

Trending insights from WhereNext and other leading publicationsTrending articles

December 5, 2024 |

November 18, 2025 |

July 25, 2023 |

September 23, 2025 |

January 6, 2026 |

November 24, 2025 | Multiple Authors |