A large steel mill can span hundreds of acres and employ thousands of employees, a profile shared by auto assembly plants, semiconductor fabs, and pharmaceutical facilities. In such environments, safety is the first priority, and efficiency runs a close second.

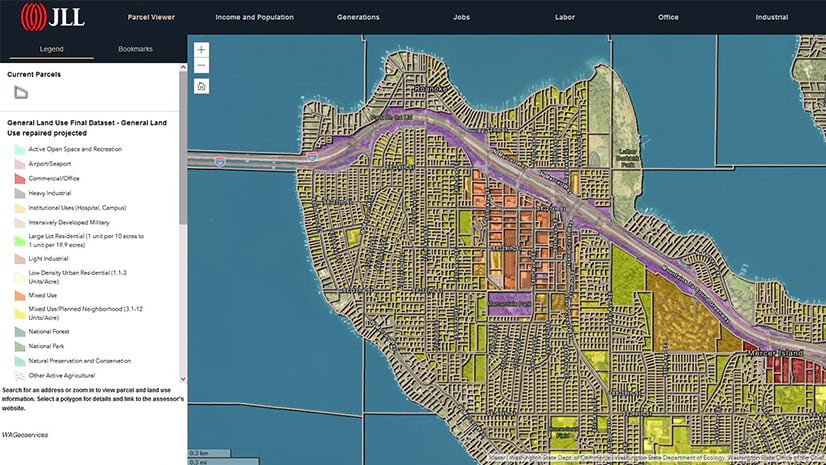

That’s why leading manufacturers are exploring digital twins to replace filing cabinets, blueprints, and printed work orders. Digital twins created with location technology provide a modern approach to manufacturing operations management, an innovative way to increase efficiency and safety in factories and warehouses.

Safety and Efficiency in Manufacturing Operations Management

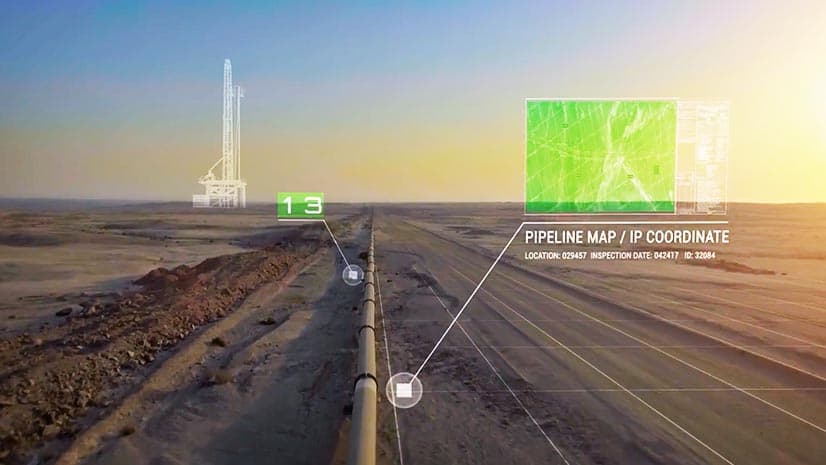

This video reveals how a digital twin created with geographic information system (GIS) technology streamlines manufacturing operations management.

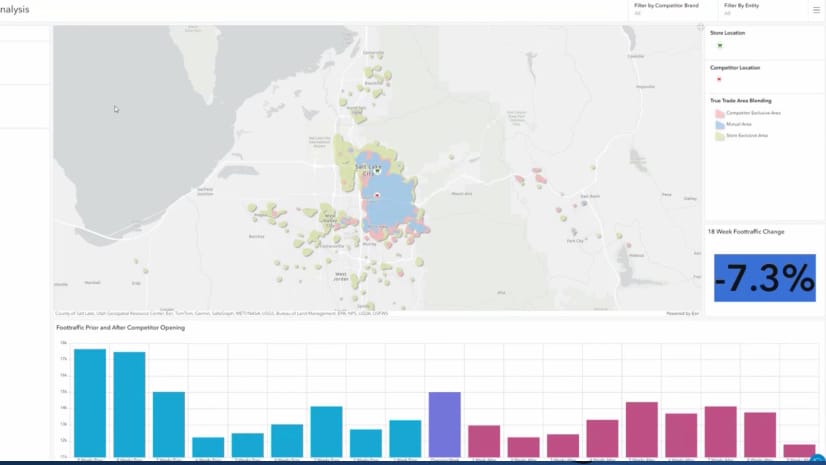

Industry-leading manufacturing sites have long stressed a safety-first culture. Location analysis unearths patterns behind incidents, like a heat map of injury data indicating where on the floor accidents occur most frequently. Visualizing these trends in a spatial context helps manufacturing leaders pinpoint causes—like a leaking pipe that’s leading to slips or a workstation drawing from a faulty batch of PPE.

A dashboard complements the map with quick-reference data, like a bar graph tracking monthly safety stats. This information might highlight seasonal trends behind poor safety performance and drive process improvements. An uptick in OSHA violations in the summer, for instance, could compel a manager to schedule more training in the spring.

Reclaiming Lost Time on the Shop Floor

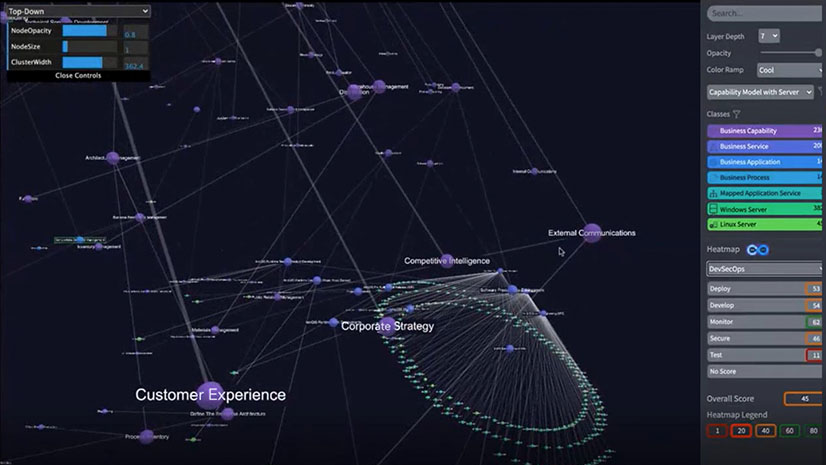

In manufacturing facilities, time spent searching for machines, data, documents, people, or parts reduces productivity. A digital twin addresses the problem by organizing information by location.

As the video demonstrates, an operations manager can see a map of an entire facility and scan the types of machinery by room and icon. To see details of a particular machine—model number or features, for instance—he or she can click the twin to bring up a photo and detailed specs.

A GIS digital twin enables better manufacturing operations management. The software helps service technicians navigate large facilities, saving time that would otherwise be lost to inefficient routing.

To determine which part needs replacement, a field technician can pull up a GIS map on a mobile device and tap the equipment icon for a PDF of its schematics. Within the same application, the technician can check maintenance records, seeing who last serviced the machine and when.

An Executive-Level View of the Modern Manufacturing Facility

For decision-makers, a digital twin powered by location technology offers an executive-level view of facility performance, enabling comparisons between operations within a plant or across a campus. On the dashboard, pie charts indicate the factory-wide status of equipment: what’s down, functional, or unused.

From the same view, a quality control supervisor can create a work order using drop-down menus that specify priority levels and assign jobs to specific employees. A dashboard offers a side-by-side view, displaying a list of orders approved or under review next to a floor map showing the location of those orders in the facility.

Effective manufacturing operations management closes information gaps between stages of the production processes. Location technology acts as a hub, connecting employees to single-source data.

A system of record for technicians, a source of insight for safety managers, and a project management tool for leaders—a GIS-based digital twin offers new levels of visibility into the inner workings of manufacturing and warehouse facilities.

The Esri Brief

Trending insights from WhereNext and other leading publicationsTrending articles

December 5, 2024 |

November 18, 2025 |

January 6, 2026 |

July 25, 2023 |

September 23, 2025 |

November 12, 2018 |