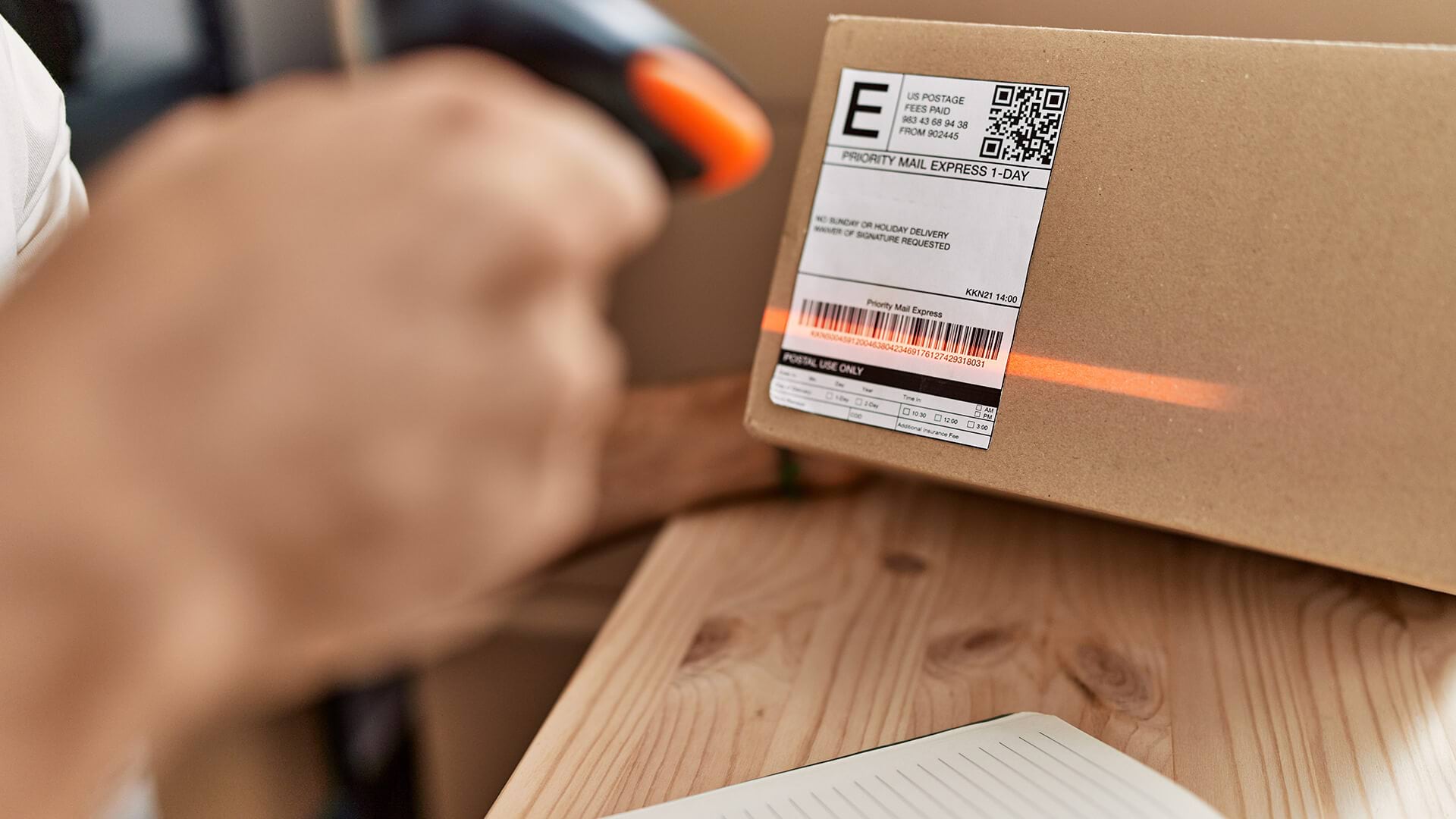

The UPC—the one-dimensional, line-based product barcode that makes checkout counters go “beep”—just turned 50. Now, the standards organization behind the code is campaigning to retire it by 2027.

Its replacement? The 2D barcode—a category of watermarks that stores significantly more information and includes smartphone-friendly QR Codes.

The transition from 1D to 2D—along with the availability of other forms of tracking such as RFID chips, telematics devices, and IoT sensors—offers companies new ways to track assets, improve supply chain efficiency, and connect with customers and employees.

At the core of these expanded capabilities is something called location intelligence—the ability to better understand what is happening throughout a product’s journey.

With their expanded data capacity, 2D barcodes provide unprecedented visibility into supply chains and products.

Smarter Supply Chains: 2D Barcodes Unlock New Possibilities

One plastic packaging manufacturer is already using QR Codes to show the circular path its products take through the supply chain.

Rehrig Pacific supplies an array of products, from shipping pallets to residential and commercial trash bins to warehouse storage bins—nearly all of which are recyclable. If a trash bin breaks and can’t be fixed, it is ground into resin, and the company uses the material to make a new trash container. At each step along that path, workers scan a QR Code that records where the batch has been. The result is a well-documented circular supply chain, visible on a smart map produced by a geographic information system (GIS). For customers seeking assurances, Rehrig can provide verified data that recycled material is indeed going full circle.

Tracking a material’s location through the supply chain can also enhance production. When a load of recycled plastic material is scanned, Rehrig’s manufacturing facility learns well in advance what’s coming and when, helping the company plan its production processes more reliably and efficiently.

Tracking Assets with Precision

The use of location-aware devices—from 2D barcodes to RFID tags and IoT sensors—extends well beyond the manufacturing arena. They can be attached to lifesaving medical equipment and viewed on a GIS map of a hospital. They can be integrated into a fleet of delivery vehicles, allowing an analyst to design faster and safer distribution routes. They might appear on an HVAC unit in a commercial building, giving maintenance technicians and inspectors contextual data on demand. Additional information can be embedded into 2D barcodes, including when an item was last serviced or when will need to be replaced, notes on its warranty or expiration, and its technical specifications.

Some companies use QR Codes to stay connected with customers who may scan a code in a store to access a survey, a virtual experience, or special deals. Barcodes can also help stores survey their own employees, taking them to a brief online form to note after each shift what is working on the sales floor and what isn’t.

As standards groups push for the wider adoption of 2D barcodes, opportunities abound for infusing these codes with information that improves the location intelligence of companies and customers alike.