In the quiet farmlands of North Carolina, the logistics analyst for a livestock farming and meat packaging company woke one morning to a 6:00 a.m. call no operations manager wants to receive. A catastrophic failure at one of the company’s East Coast manufacturing facilities threatened losses of up to 15 percent of the region’s animal feed supply.

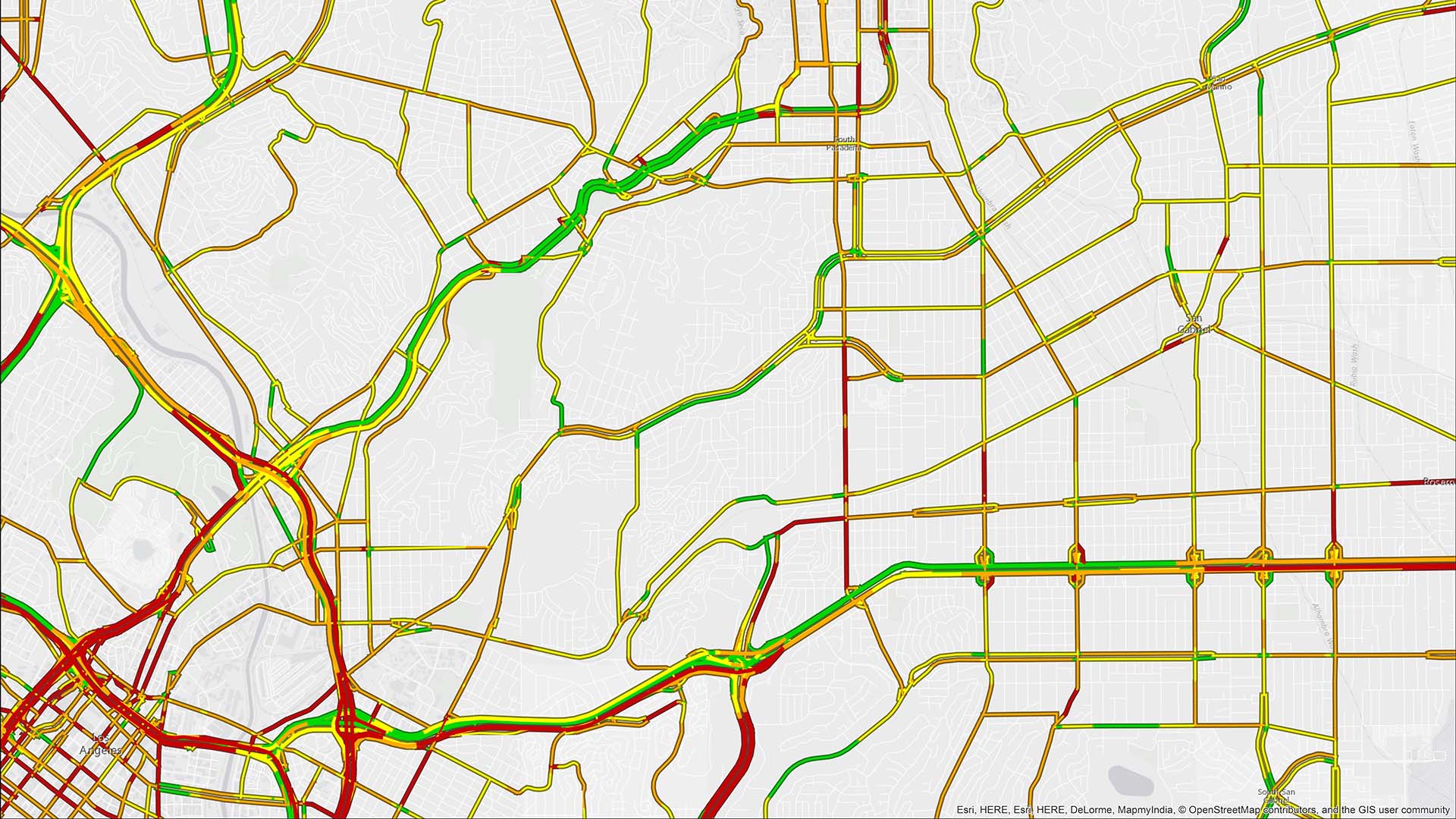

By the end of that day, the company had rerouted the entire supply chain around the shutdown–keeping deliveries of feed on schedule at minimal cost. How did they do it? Geographic information system (GIS) technology that transformed a potential crisis into a manageable disruption.

Thousands of businesses—freight shipping companies, package delivery services, retailers, quick service restaurants, even pest control companies and agtech firms—use GIS analysis to optimize routes and streamline distribution networks. The financial and time savings can be significant. One major logistics company credits GIS-powered location intelligence with cutting millions of dollars from transportation spending each year.

That morning in North Carolina, GIS analysis resolved a fast-moving situation while keeping feed deliveries to farms on schedule.

“We were able to leverage the tools and models we built to quickly respond … at a minimal cost of interruption,” the analyst says. “We had a plan in place to reroute all our feed deliveries by the end of the day.”

An Insider’s View: Taming Distribution Networks with Location Analytics

While global supply chains often make headlines, the impact of GIS on local supply chains and last-mile logistics remains something of an untold story.

WhereNext spoke with three industry insiders who have significantly reduced inefficiencies and ensured the timely delivery of goods and services using location technology.

If routing were as straightforward as finding the quickest path between two or more points, most planners could do it with a simple web map. And while some try, they quickly find that the practice doesn’t scale.

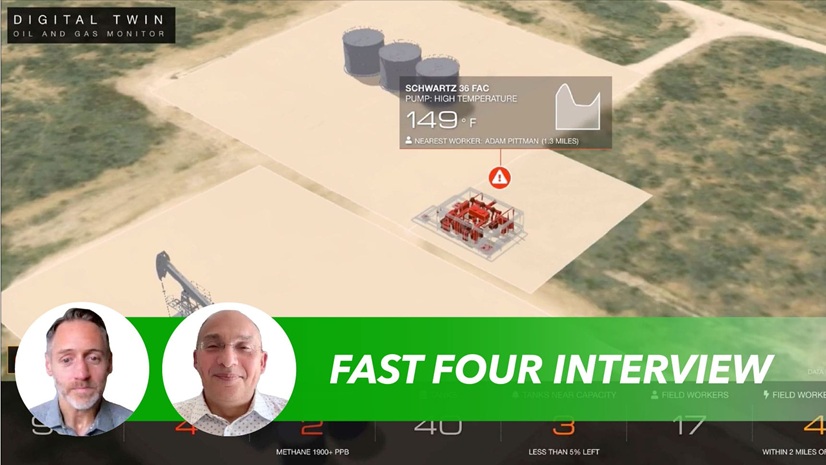

Operations managers must design service and distribution networks that honor a complex matrix of variables and constraints—drop-off windows, perishable goods, work shifts, asset availability, and warehouse capacity—as well as real-time events, like road closures, pandemics, and natural disasters.

Accounting for those conditions while coordinating the movements of large fleets of vehicles or thousands of mobile workers creates computational problems that strain the abilities of all but the most sophisticated software.

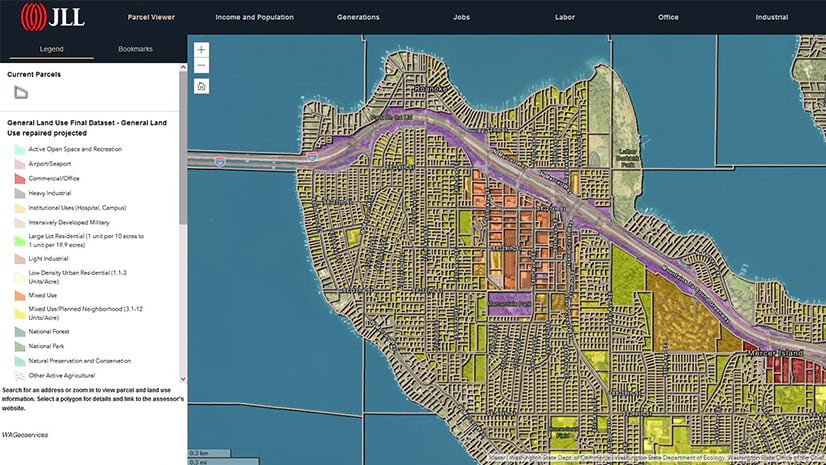

Logistics engineers and transportation directors turn to GIS for its advanced route solvers—the algorithms that automatically generate the fastest, most efficient paths between multiple stops based on dozens of inputs.

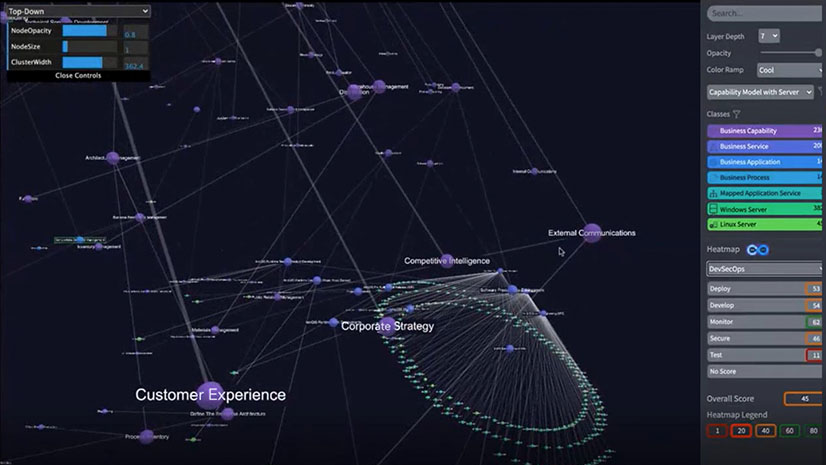

GIS analytics also helps planners optimize the layout of supply chains and distribution networks. For instance, location analysis enables freight shippers to site loading docks where they will minimize the total weight of cargo moved between warehouses and manufacturing facilities.

“What it comes down to is how to spend millions of dollars of capital and have the confidence to know that where you’re spending your money is going to improve your network,” says one geographic data scientist who helps site distribution centers for a quick service restaurant.

When Supply Chains Go Awry, GIS Analysts Get the Call

For the North Carolina logistics analyst, 6:00 a.m. emergencies are mercifully rare, but he frequently finds himself in demand when senior leaders discover waste or notice that KPIs are amiss.

Location analysis helps the business tighten delivery routes between the manufacturing facilities that supply livestock feed, the facilities that raise and process the animals, and the support and storage buildings that help manage the flow of raw materials.

Prior to the introduction of GIS, drivers had to navigate 1,200 miles of private roads to reach these destinations, relying on little more than memory and word of mouth. Today, routing applications enable drivers to find the most efficient multi-stop paths among 25,000 destinations.

In 2020, the logistics analyst worked on a project that received an internal award for achieving significant ROI. He and a team of colleagues used GIS analysis to reconfigure the routes from farms to processing facilities. The optimization saved more than 50,000 gallons of diesel fuel and reduced the associated emissions by 18 percent.

“It really helped us get the right product into the right places, minimizing the overall freight distance we had to move it,” he says of the GIS results.

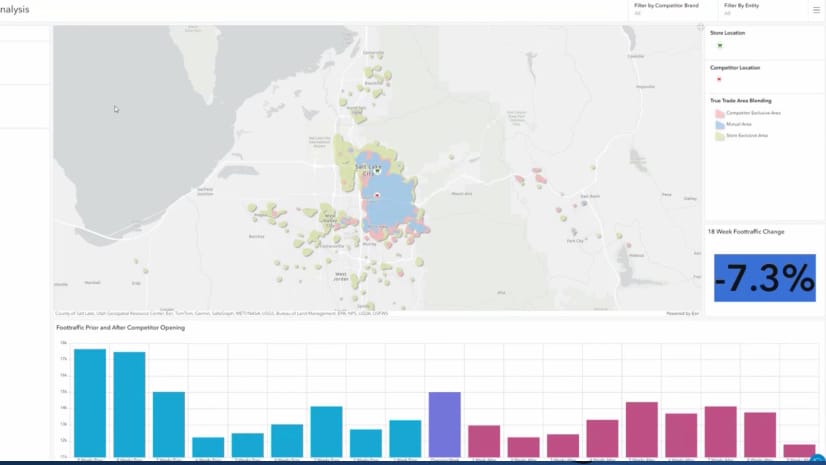

More recently, the same location tools created an efficient solution for another issue: moving feed from eight mills to over 1,600 farms, while accounting for the different feed rations produced at each mill as well as the level of grain production in different regions and the prices in those markets.

Over time we’ve used GIS tools to evaluate from a freight perspective and cost perspective to optimize the movement of things through our system.

Using Smart Maps to Balance Service and Labor Constraints

Many businesses are interested in charting the quickest, most cost-effective path between destinations. For other firms—like a street-sweeping service provider—it’s quite literally the journey that matters.

When a company must travel prescribed routes, optimization is less about which road to take and more about other efficiencies, such as the fastest way to sweep both sides of a highway shoulder, or how best to apportion work zones that balance customer needs and workforce availability. Untangling those complexities requires a precise grasp of geography.

The GIS program manager at one street-sweeping company uses smart maps to draw up service territories so that each driver works within a prescribed geographic zone. With 10,000 customers, these maps help the business ensure coverage for clients while complying with regulations that govern how long an operator can drive.

“We’ve tried to develop a system where we can move operators around,” the manager explains. “Hopefully you would be able to take an operator from Atlanta and drop him into an operation in Texas, and he would know exactly what to do based on the information we’re able to provide.”

In the future, the program manager anticipates using location analysis to boost productivity by routing drivers to new jobs if they finish an assignment early, or locating the nearest available unit if a truck breaks down.

Our GIS utilization creates more manageable chunks of work for our operators.

Network Planning: The Foundation of Route Efficiency

If service depots and warehouses aren’t strategically located throughout a distribution network, a company will regularly lose time and money that no routing algorithm can replace.

For the GIS data scientist at one fast-food chain, analyzing a distribution network used to be a weeks-long endeavor.

In the past, “it was a very manual and laborious process,” to estimate the capacity of a growing network, he told WhereNext. Now, using location analytics, “it’s less than 10 minutes for the entire 10-year forecast.”

The business operates roughly 20 distribution centers nationwide, servicing nearly 7,000 stores. The GIS data scientist helps his supply chain colleagues ensure that DCs maximize capacity while minimizing transportation costs.

The GIS tool he developed enables logistics engineers to test scenarios for the network’s future. Based on several variables—the number of new stores opening each year, the current distribution center locations, and the anticipated growth in customer demand—the application forecasts capacity utilization for each center over the next 10 years. Operations managers use the tool to compare cost and capacity metrics for multiple locations.

The fact that colleagues can access the technology in a self-service manner has freed up both teams for higher-value work, he says. “We give them the data and tools to make their own decisions. We set them up for success in that way.”

Routing Algorithms on the Screen, Real Impacts on the Road

To see firsthand how location analysis impacts company operations, the analyst for the meat-packing firm goes on ride-alongs with truck drivers.

Traveling down dusty farm roads that were once tracked only in three-ring binders on handwritten notes, he sees how GIS routing saves hours of time for people in the field and the organizations they support.

“You turn off the road, and you might be in the middle of nowhere,” he says. “With our tools, you punch in one of these facilities and it gives you as much as four more miles of directions. Seeing that in person, it really sets in.”

The Esri Brief

Trending insights from WhereNext and other leading publicationsTrending articles

December 5, 2024 |

November 18, 2025 |

July 25, 2023 |

September 23, 2025 |

January 6, 2026 |

November 24, 2025 | Multiple Authors |