Does the airline industry have a hoarding problem?

That’s one conclusion reached by the International Air Transport Association (IATA) in a report on the industry’s supply chain challenges. The global trade group claims that commercial airlines must maintain huge storehouses of spare parts to operate with minimal interruption.

In an industry where operational efficiency determines survival, supply chain efficiency starts with two basic questions: Where are the parts, and how fast can they get to where they’re needed?

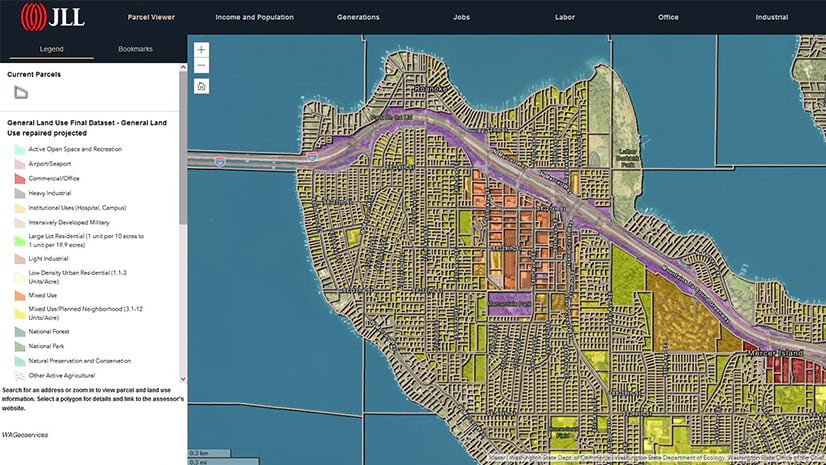

For top global companies, the answers start with operational awareness created by smart maps—real-time visibility into assets, inventory, and logistics networks spanning continents.

Locating Spare Parts

As of 2025, most industrial supply chains have meaningfully rebounded from pandemic-induced disruptions, but airlines are an exception, according to the IATA.

The trade group blames changes to the business models of engine and equipment system manufacturers, claiming these companies now concentrate more on aftermarket revenue. By prioritizing repair work and spare parts sales over delivering new equipment, the study claims, these companies contribute to a slower rollout of new airplanes.

Forced to keep older aircraft flying, airlines must hold more spare parts than they need, according to the IATA. This creates significant expense, including increased investment in storage, inventory management, and compliance assurance—as well as the opportunity cost of tying up capital that could be allocated elsewhere.

Increased Efficiency

By the IATA’s accounting, the cost to commercial airlines of holding excess inventory is $1.4 billion annually.

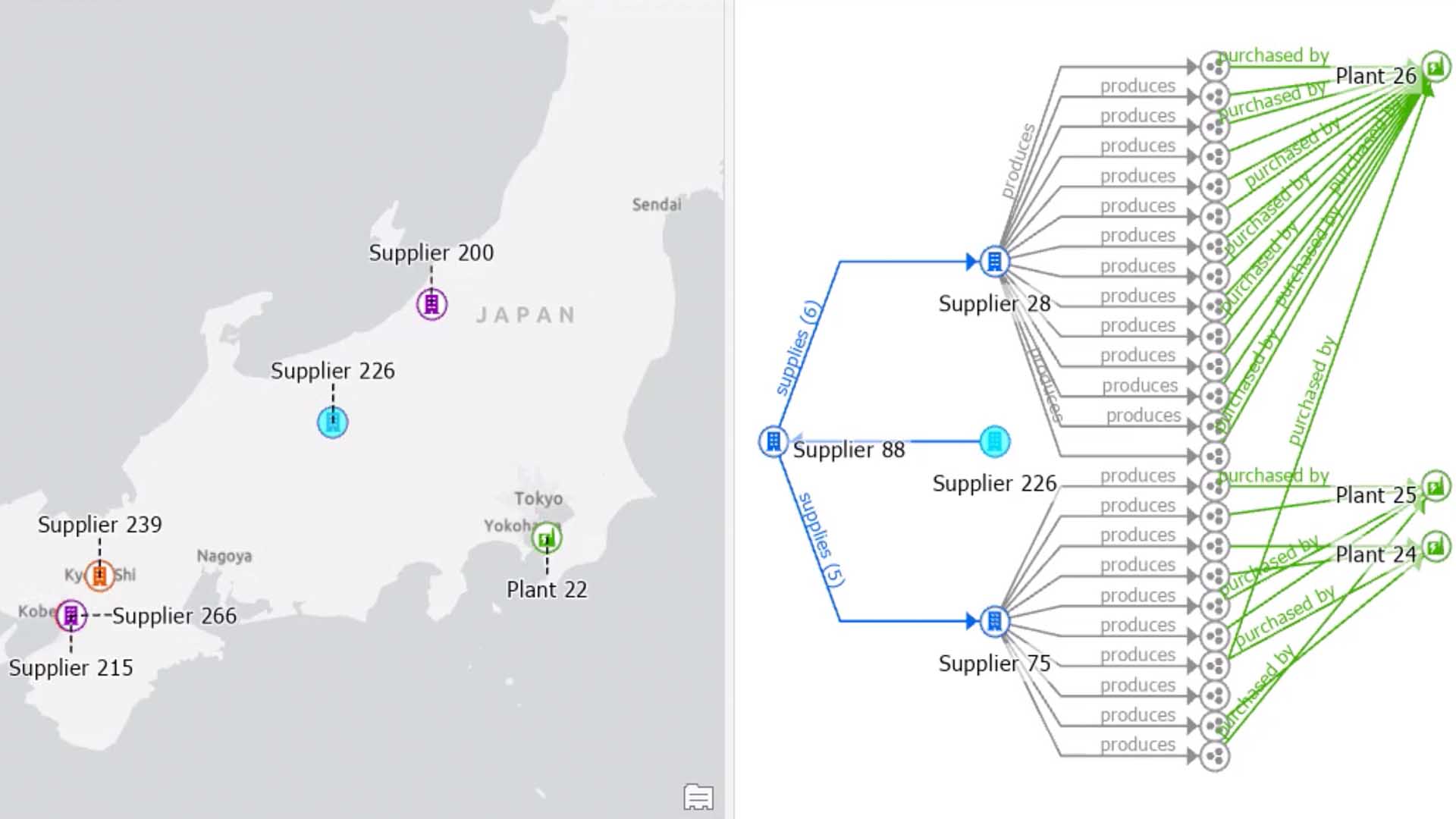

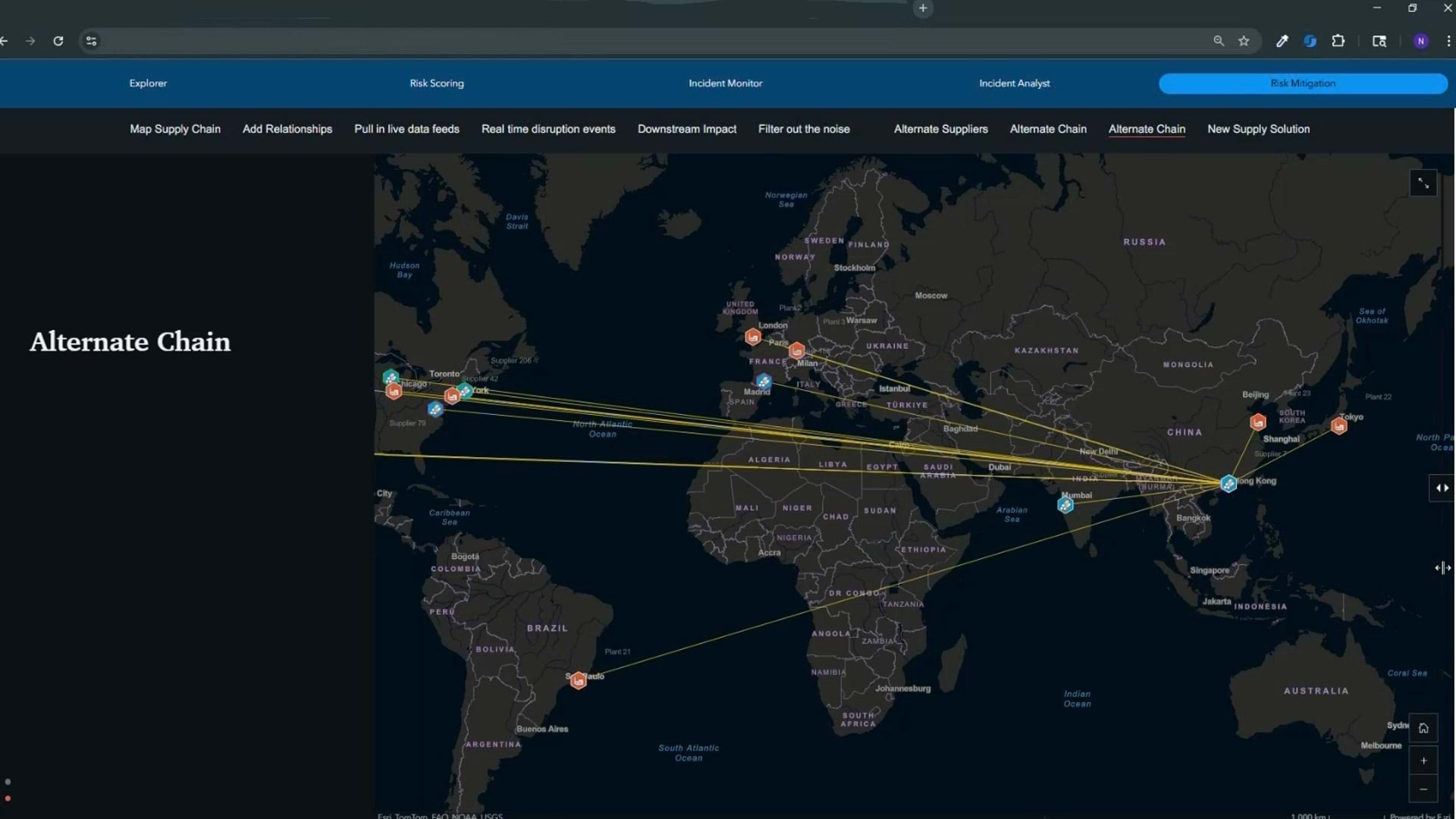

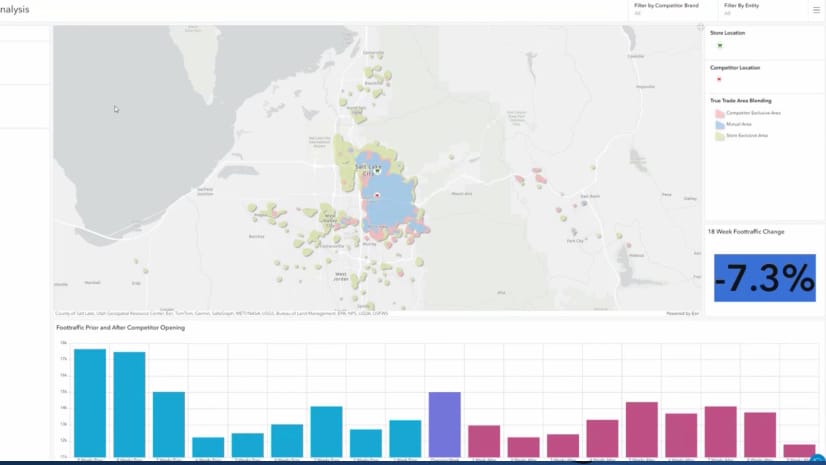

One way other industries have driven down inventory costs is through smart maps, made with geographic information system (GIS) technology, which provide real-time or near real-time views of global operations.

Consider one of the world’s largest global delivery services. The grounding of a single aircraft can affect the delivery of thousands of customer packages. Even a single flight delay can create ripple effects throughout the system.

The company relies on GIS software for a real-time map of its network, including the locations of planes, parts, and pilots. This allows logistics managers to make informed decisions about how to keep the fleet running smoothly.

Every asset—from the plane itself to the thousands of parts it needs to operate—is tracked in the system. This location awareness drives efficient inventory management, with the company moving spare parts through the network on demand. It also helps the company spot possible complications on the horizon—before they lead to major disruptions.

Smart maps deliver operational intelligence where it’s needed, when it’s needed by creating a nerve center that runs throughout the organization. Mechanics on the runway use handheld devices to find information on required parts. Flight planners use maps to understand whether mechanical issues will require rescheduling. And logistics managers see the whole system on a single pane of glass.

From Digital Maps to Digital Twins

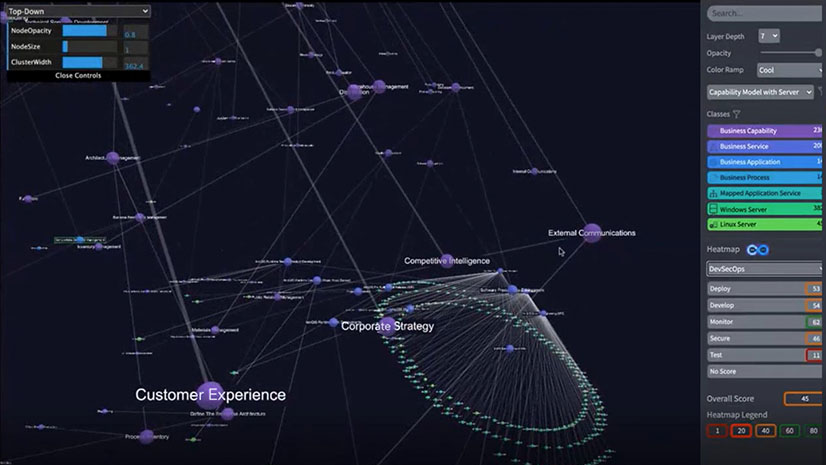

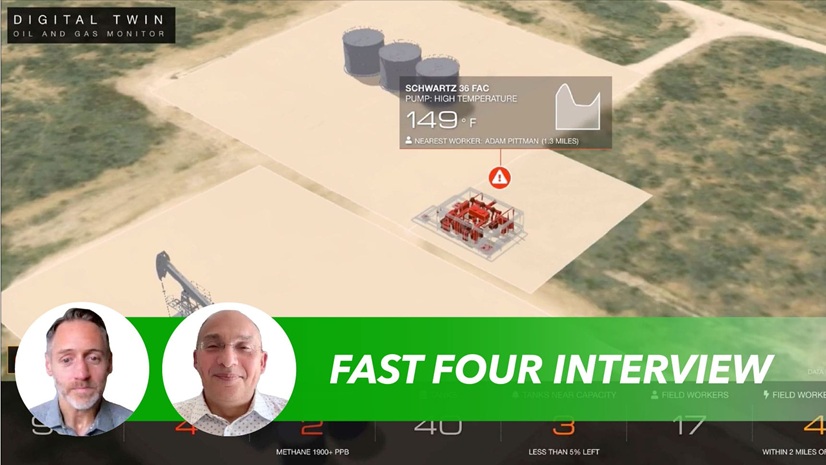

Some companies consider GIS maps the digital twins of their operations.

One IT company whose equipment powers data centers worldwide built a GIS digital twin it calls the “central nervous system” of its service supply chain. Its smart maps have replaced spreadsheets, connecting logistics, field services, planning, order management, and sales support teams.

With a clear view of which technicians are closest to which customers, the company identifies the right specialist for every customer appointment. GIS maps also pull data from a spare parts management system, providing additional operational intelligence for efficient service calls.

As leading companies switch from data-dense spreadsheets to the clarity of smart maps, they’re achieving new levels of operational efficiency. For airlines facing supply chain challenges, the first step to better inventory management may be a clearer view.

The Esri Brief

Trending insights from WhereNext and other leading publicationsTrending articles

December 5, 2024 |

November 18, 2025 |

July 25, 2023 |

September 23, 2025 |

January 6, 2026 |

November 24, 2025 | Multiple Authors |