Imagine a supply chain delivering parts and service to millions of customer sites in more than 130 countries—often within two hours of a customer’s request. That’s a challenge we take seriously at Cisco, where every minute of downtime can cost our customers revenue.

As a large IT company, Cisco knows how to be in many places at once and still provide service that feels personal. That gives Cisco an edge in the hypercompetitive market for networking and security technology.

To deliver fast and effective technical support, the company relies in part on a digital twin powered by geographic information system (GIS) technology. The location intelligence we derive from this digital twin helps us manage a service supply chain of global complexity—while maintaining high levels of customer satisfaction.

A Digital Twin for the Service Supply Chain

Cisco’s service supply chain repairs and replaces products ranging from servers in data centers and networking switches to video conferencing systems in offices and executive boardrooms.

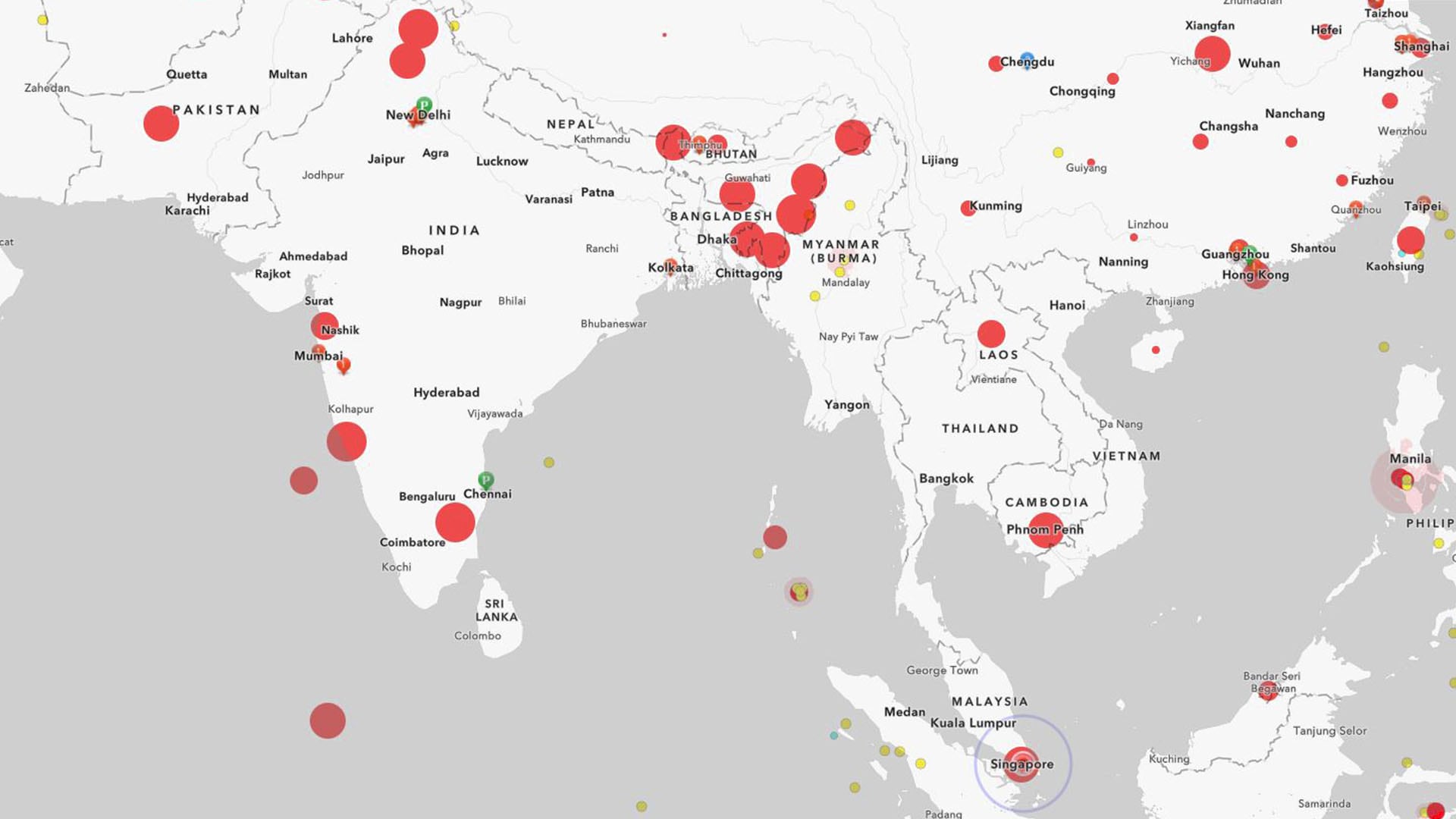

At the heart of our service network are the global and local vendors who fulfill a wide range of service-level commitments for Cisco customers. Collectively, these vendors manage more than 1,300 warehouses for spare part positioning and allow us to leverage a global field services force of thousands of engineers.

To ensure that the service supply chain runs efficiently, we created a digital twin called the Service Delivery Insights Platform (SDIP), a central nervous system connecting logistics, field services, planning, order management, and sales support. Fueled by a set of business rules and GIS-based location intelligence, the SDIP provides near-real-time awareness, allowing us to dispatch spare parts and technicians from the most appropriate warehouse and engineer base. This has improved spare-part inventory planning and field service team availability.

With GIS as its core, the SDIP acts as an intelligent mapping platform, displaying vendors’ service capabilities and response areas. The SDIP also displays a digital twin of the road network, automatically calculates how far vendors can travel to deliver service in a region, and assesses shipping methods for spare-parts delivery.

To optimize service delivery, the SDIP matches the right talent and depot location to the customer’s need by assessing engineers’ technical skills and warehouse processing times. In doing so, it helps us meet service delivery deadlines and customer expectations.

This innovative system takes automation to a new level, enabling Cisco’s service supply chain to adapt quickly to the realities of each customer and region.

For any business that relies on delivering services or parts to customers effectively, location intelligence is a must-have capability.

Investing in Location Intelligence Improves Outcomes

The transformation of Cisco’s service supply chain from a spreadsheet-based process to a near real-time digital twin represents an investment in reliable data, intelligent systems, and—most of all—our customers. The SDIP thrives on geographic data, and ensuring the precision of this data is an ongoing process of simplification. We recently transitioned from maintaining millions of destination addresses to only maintaining our dispatch locations, letting the system calculate the service coverage area for each. This has led to a near elimination of data maintenance, and has fueled many of our service improvements.

When a Cisco customer submits a return material authorization (RMA), the SDIP automatically recognizes the customer address and calculates which of our 1,300 warehouses can reach that location within the contractually specified time. The system then checks available parts inventory nearby and analyzes local and international trade barriers that could limit border crossings. The result may show that multiple warehouses can serve the customer, so GIS weighs distance and drive-time considerations to select the one most suitable to dispatch the part.

Because we have customers across the globe, this activity goes on around the clock. The assignment process is complex, especially when calls are routed to a country with different trade restrictions and tax jurisdictions. The SDIP automates the assignment process, checking established business rules and dispatching the request to the right warehouse—avoiding human error and accelerating execution. This level of automation enables Cisco to handle hundreds of thousands of RMAs each year.

We are experimenting with integrating real-time traffic and weather information into the digital twin to help field service engineers reach customer sites safely and even quicker. Through this automated location intelligence, we will be better equipped to achieve the ultimate goal of having the part and the engineer arrive simultaneously.

Cisco’s use of GIS has yielded several benefits: More efficient parts routing, smarter warehouse locations, optimized inventory, and—most important—the ability to better meet a wider range of customer needs.

Inventory Optimization

As a company that prides itself on exceptional customer service, Cisco values a highly accurate view of our service capabilities. Location intelligence helps answer crucial questions such as: Where are our service gaps? Where do we already sell a service and where do we need to add depots? Where do we have too many warehouses?

GIS technology helped us see that we had significant overlap in our service areas and allowed us to right-size our warehouse network and inventory. Previously, one city might have been reached by several warehouses, and there was no hierarchy governing how a customer was assigned to a particular warehouse. By applying location intelligence and business rules through GIS, we ensured the right locations for our warehouse network.

This optimization spurs higher ROI. We’ve been able to reduce unnecessary inventory and phase out redundant depots. When you consider the size of our spare parts inventory—valued in the billions of dollars—and the fact that SDIP has contributed to inventory savings alone in the high single digits, you can glean how significant these changes have been to our global operations.

The Value of Innovation

Honoring our commitments to millions of customers in more than 130 countries is a critical mission at Cisco. In a fast-paced global marketplace, the geospatially enabled SDIP delivers value not only by improving customer uptime, but by improving operations in other areas of our business.

Globally, Cisco stocks hundreds of thousands of service parts, and our logistics team has used the location intelligence derived from SDIP to create a hub-and-spoke distribution model. The resultant economies of scale have helped us significantly improve spare-parts inventory positioning

With GIS technology delivering up-to-date location information to SDIP’s digital twin, our team can focus on the value-rich work of improving customer experience, rather than on data curation.

SDIP also improves territory accuracy and visibility by creating a reliable single source of truth for Cisco’s global service supply chain. The system automatically assigns new customers to the appropriate depot and adjusts assignments when warehouses move, or configurations are altered.

The system captures and recognizes trade barriers in a manner designed to ensure compliance with local and global trade restrictions and quickly updates coverage capabilities when road networks are expanded.

With GIS technology as a foundational component in Cisco’s Service Delivery Insights Platform, the company continues to drive digitization, automation, and operational efficiencies, delivering reliable service for customers who need dedicated support to ensure business continuity.