Businesses that have mastered the new supply chain have embraced one key learning: real-time digital awareness informs the best physical response.

In the months and years to come, more supply chain operators will capitalize on this knowledge, and most will discover that a digital twin of the supply chain leads them directly to the right physical, real-world response.

See It They Must

In the last decade, the world of the supply chain operator has changed dramatically, creating both high risk and huge opportunity.

Consider the advent of the Internet of Things (IoT). Now that connectivity is becoming ubiquitous, almost anything in the supply chain can be tracked in real time—not just finished goods but also the tires on the truck, the wings on the plane, and the pallets that transport the goods. In addition, new forms of digital information are now available from third parties—pinpoint weather warnings, social media sentiment, and traffic alerts and hazards. This expanding set of digital intelligence has yielded an overwhelming amount of data that companies are struggling to leverage so they can make sense of the most urgent situations.

On the demand side, today’s global consumer—empowered by information and high on expectations—has fueled a right-now economy that forces businesses and supply chains to accelerate both their decision-making and their quality delivery of products and services. Combine that pressure with an ever more complex network of supply partners (and partners of partners), and a supply chain leader’s ability to see it all clearly—let alone manage it effectively—is challenged significantly.

But see it they must.

The idea that manufacturing is dead, or retail is dead, is an absolute fallacy. In the history of the planet, we've never built, bought, or sold more goods than we do now. And it will only increase.

Rising Expectations

These days, Amazon is as good a barometer of supply chain demands as almost any single company, and analysts estimate that the e-commerce giant’s Prime two-day delivery service is now serving more than 50 percent of American households. That uptake has rippled across the supply chain, as companies look to deliver not just the speed that consumers crave but also the transparency and accuracy they expect.

According to Supply Chain Quarterly, a 2016 Dotcom Distribution survey found that “almost half (47 percent) of shoppers said they had chosen not to order from a retailer again because of poor order transparency about their package status during the fulfillment and delivery process.”

Logistics providers—UPS among them—have a close-up view of this empowered consumer.

“When I started over 40 years ago, getting a package cross-country in five or six days was a miracle,” UPS executive Jack Levis said in a recent podcast interview. “Nowadays, people want their delivery experience where they want it, how they want it, when they want it.”

These expectations have changed business, in part by compressing decision cycles for supply chains worldwide. Executives no longer have a two- or three-day time frame to determine what’s best. Smart decisions must be made in minutes, if not seconds, by empowered employees on the front lines of the business.

The best response, according to Deloitte, is not an iteration on traditional thinking but rather a revolution.

“For business leaders accustomed to traditional linear data and communications, the shift to real-time access to data and intelligence fundamentally transforms the way they conduct business,” Deloitte analysts wrote in the 2016 report The Rise of the Digital Supply Network.

Meet Your Twin

In the modern world of commerce, the supply chain is always on, always connected, always producing data. To excel in this environment, and to leverage that information for maximum value, some forward-thinking companies are beginning to apply the digital twin concept to their supply chains.

A digital twin is a virtual replica of physical assets, processes, or systems. As physical conditions change, the digital twin logs those changes in real time—whether it’s a shipment of subassemblies delayed by a parts shortage, a delivery truck waylaid by a traffic hazard, a distribution center’s operations threatened by extreme weather, or a service provider completing a maintenance job.

The digital twin creates a physical-to-digital-to-physical loop that allows a company to quickly and continually fine-tune its live network.

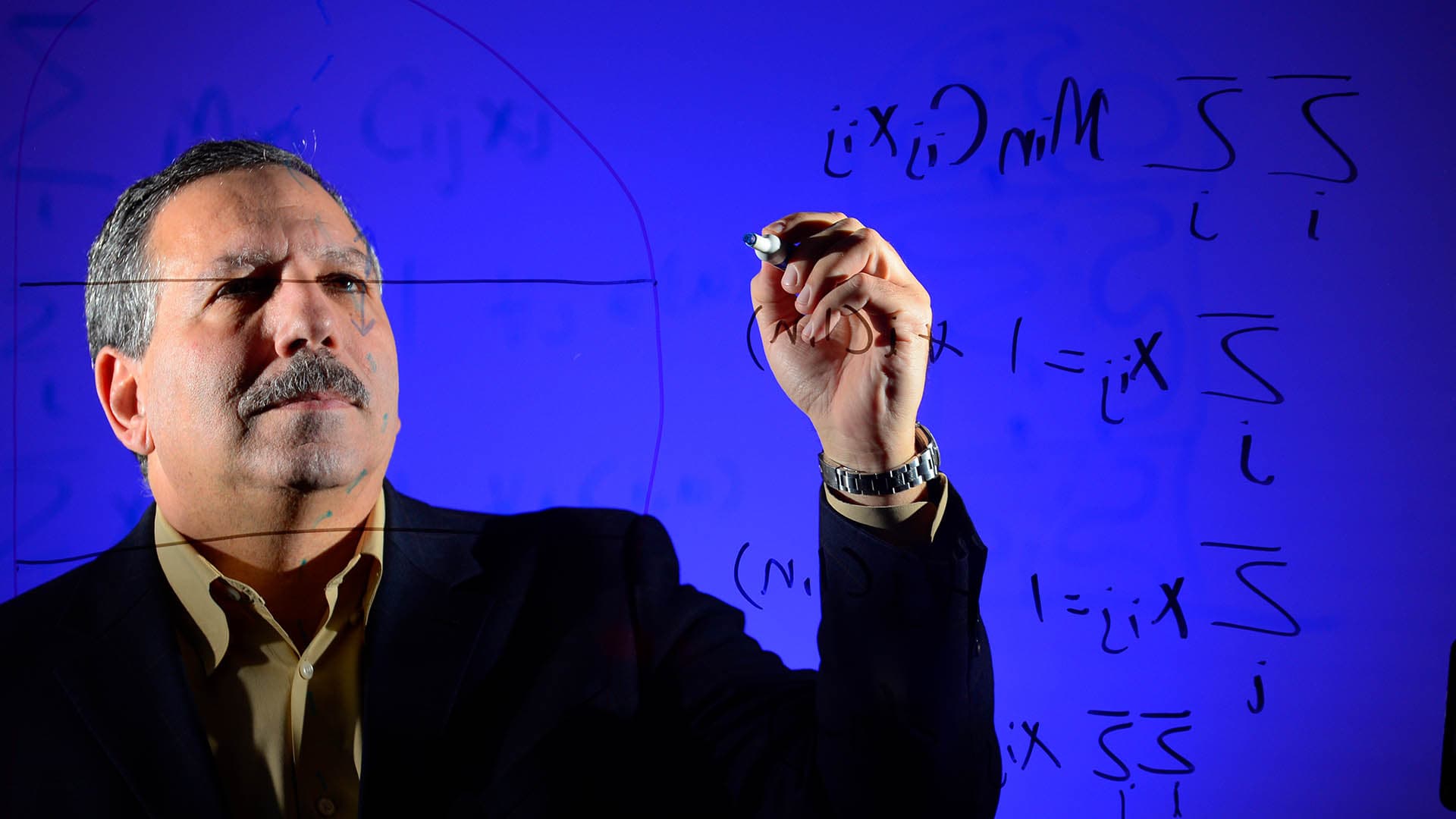

“What we’re talking about is making a connection between those two realities, the virtual and the physical . . . so that what happens in the physical world is immediately reflected in the virtual reality,” says Morgan Swink, professor of supply chain management at Texas Christian University’s Neeley School of Business. The upshot, he continues, is that companies can make more intelligent decisions and adapt to changing conditions faster than ever.

Capturing physical changes as digital information gives companies a global operating picture of how their supply network is performing. It also quickens their reaction time, moving companies closer to satisfying the demands of the empowered consumer.

In short, digital awareness informs the physical response, then refreshes the digital record.

I think the supply chain is in a position now that [supply chain executives] can really make a difference for business growth and be the real change agents as we move into the digitization of the supply chain.

Manufacturers, retailers, and other supply chain operators have some of the components of the digital twin in place—MES, SCM, ERP, and CRM software to manage production; logistics and suppliers; procurement; and customer commitments. Some already use a geographic information system (GIS) to track assets and processes wherever they are in the world.

But only a pioneering few are starting to fuse these systems to construct the always-on connectivity that creates the real-time track-and-trace capability that a supply chain digital twin demands.

Next Generation Benefits

In the tradition-bound world of supply chain management, some executives might wonder why they would invest in such an integration.

In its report, Deloitte notes several business benefits of what it calls the digital supply network:

- Always-on agility: A company that augments traditional supply chain information with new sensor-based and location-aware data gives itself the ability to respond rapidly to changing circumstances and unforeseen conditions.

- Connected community: By enabling real-time communication and collaboration with suppliers, partners, and customers, supply chain organizations can make decisions based on reliable, up-to-date data.

- Intelligent optimization: By combining data from humans and machines with advanced analytics and predictive insights, supply chain operators can optimize human-machine decision-making.

- End-to-end transparency: Digital technology provides the ability to see across the supply chain at any moment, improving visibility into critical aspects of its performance. This transparency offers a host of benefits, from material flow tracking and schedule synchronization to an improved capability to balance supply and demand.

- Holistic decision-making: With a global operating view of the supply chain, a business can understand the ramifications of decisions across business functions, including how they will impact financial objectives and what tradeoffs they create.

A welcome by-product of these benefits is increased customer engagement. By creating a stronger connection with customers, companies can better tailor buying and service experiences that keep customers loyal to the brand and expand the company’s share of wallet.

Action through a Digital Twin

In daily business operations, the supply chain digital twin can demonstrate its value in many ways. Consider goods in transit. In the unfortunate event that a catastrophic incident temporarily closes a bridge or thoroughfare in a major European city, the appropriate supply chain manager can receive a real-time alert once a service level is at risk and gain explicit insight into the issue without having to sort through irrelevant information. With that pinpoint digital awareness, the company can shape its physical response, rerouting deliveries as quickly and efficiently as possible.

Now imagine analyzing the same delivery routes through a historical lens. Using information collected by the digital twin, a supply chain analyst can examine the last six months of deliveries, all the way from production through final mile. In that light, recurring weaknesses reveal themselves and enable planners to remap operations most efficiently.

The biggest inhibitor to creating a digital twin of the supply chain is traditional thinking. Companies are still trying to manage the supply chain as a point-to-point, linear endeavor. But it's not linear anymore. It's a spider web.

The digital twin can prove invaluable in the case of product recalls. With IoT technology helping to trace products from farm to table, a food producer can view on a map the full path of a tainted product batch. With that insight, the company can identify the contaminant faster and limit the recall to tainted products.

TCU’s Swink says financial operations are also a worthy target for digitization. An oil and gas company he works with is essentially creating a real-time digital twin of financial transactions—purchases of sand, chemicals, and services—at the well site that keep operations running smoothly. Until recently, those transactions occurred offline and only appeared months later when invoices were added to the system. Digitizing that procure-to-pay function, which involves millions of dollars in purchases, can open the door to substantial savings.

“Suppose I’ve got several well sites that are close by to each other, and they need similar services,” Swink explains. “Now I can start to consolidate some of that work, contract at a higher level, get some real efficiencies, and leverage with my suppliers [and] manage cash flows better.”

All, he says, “because I have that real-time insight.”

The Future at Hand

Adoption of digital twin techniques varies widely across the supply chain. Many companies still trade paper invoices and faxes on a daily basis. At the other end of the spectrum, a progressive few have embraced digitization and have done so not only to cut costs but to elevate the supply chain’s contribution to growing revenues.

The maturity curve for companies applying the digital twin concept to the supply chain can look like this:

- Real-time mitigation—Understand which parts of the supply chain are under threat right now, and use digital awareness to make the best, fastest decisions possible. Start anywhere and continue to expand the digital connections when and where possible.

- Long-term optimization—Analyze historical supply chain strengths and weaknesses to improve overall performance. Extract best practices from areas of favorable key performance indicators (KPIs) while learning lessons from areas that aren’t producing the speed, transparency, and accuracy demanded by empowered consumers.

- Strategic impact—Make the supply chain a strategic contributor to the boardroom. Instead of treating it as a cost center, create a supply chain that senses where the strongest market opportunity is, who’s buying the product, and how they’re using it, and uncovers global trends that can inform new products and services.

Deloitte says in its report that digital supply networks will “allow supply chains to become an integral part of strategic planning and decision-making.” Swink and other industry veterans applaud that elevated role.

“I love to talk with executives about the potential for supply chain to be a revenue driver . . . a value-generation engine within companies,” Swink says. “There’s tremendous potential for supply chain to create new value through its use of digital technologies.”

Many companies that work in the supply chain are hard-pressed to envision such a dramatic change in a short period of time. But those who study the industry say the change is indeed coming, and it will accelerate at an unprecedented rate.

With all the information and intelligence we get through digitization and real-time insight, both supply and demand sides of the business will be transformed.

Dave Malenfant, director of the Center for Supply Chain Innovation and Swink’s colleague at TCU, recalls a conference in Dallas earlier this year. After Swink delivered a presentation focused on how digitization will engulf the supply chain, one supply chain practitioner approached colleagues with a straightforward retort: “It’s never going to happen.”

“I think that’s probably a more common opinion than we think,” Malenfant says. “And we need to try to shift that paradigm, because it is going to happen. It’s going to come much quicker than we think.”

To hear more about the digital twin concept, listen to a recent podcast “The Three Stages of Digital Transformation.”