One prominent Fortune 200 manufacturer is using location intelligence to redraw its service territories so technicians reach the right customer at the right time. Another is using location analysis to streamline its global supply chain, keeping products flowing to customers and avoiding significant operational expense.

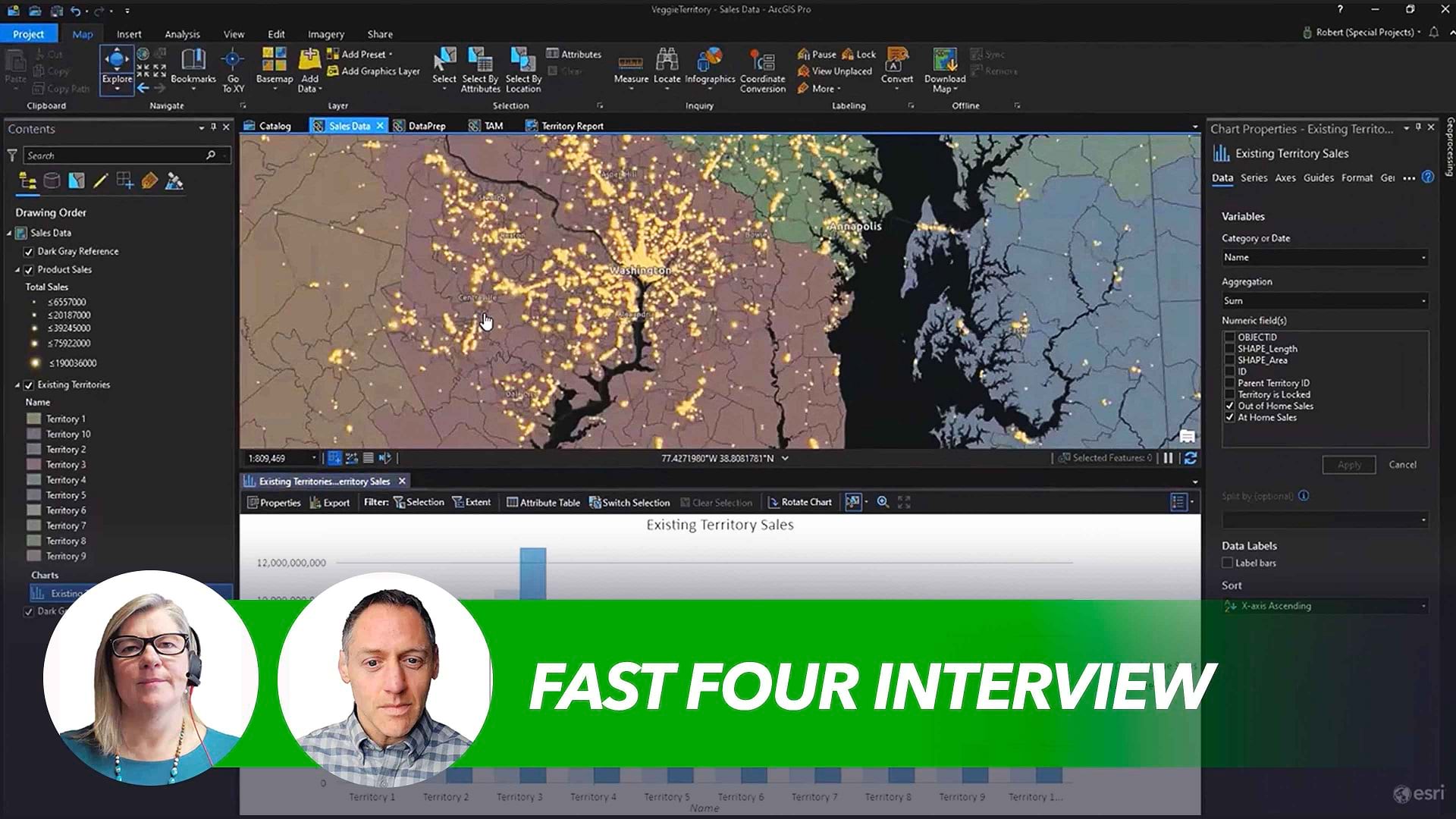

The engine of insight for both companies is the enterprise technology known as a geographic information system, or GIS. In this WhereNext Fast Four, Nikki Paripovich Stifle offers a short yet detailed look at how GIS has impacted manufacturing in recent years, and how industry standouts are innovating with help from next generation location intelligence.

Watch the video interview or read the transcript below.

For more industry insider interviews, visit WhereNext‘s Fast Four library.

Chris Chiappinelli: Welcome to the WhereNext Fast Four, where we explore how location technology is driving innovation in the business world. Today, we’re going to focus on manufacturing with Nikki Paripovich Stifle. She’ll explain how manufacturing and service companies are using geographic information systems, or GIS, to get a business edge. Nikki, at the beginning of our Fast Fours, we like to rewind a bit. I’m curious what drew manufacturers to location technology in the early days.

Nikki Paripovich Stifle: Well, it was all about business expansion, Chris. Manufacturers needed to establish where their customers and competitors were and how many dealers the company was going to need to achieve its revenue goals. They also wanted to make sure that those dealers didn’t compete with each other in the same area. So, maps and geographic analysis helped with this expansion and territory planning. With a map of the sales potential and the competitors, business leaders were able to divide up their market and align with the dealers and the sales teams on the responsibilities, and then track that growth over time.

Chiappinelli: So, understanding the market, understanding some internal competition dynamics there. What about now? As you watch companies today and work with them, how are they using location analysis? Can you share a couple of examples?

Paripovich Stifle: Absolutely. That original use case is still expanding, which is fantastic. But when I think about GIS use in manufacturing, I really look at it from the lens of risk and reward, really what supports revenue and what reduces risk.

On the side of reward, companies are looking to improve quality time with customers and deliver reliable service. A Fortune 200 manufacturer that we’re working with now is using geographic analysis to create service areas that allow technicians to spend more time at the customer site and less time on the road. And the territories that result from this analysis are really rightsized to meet the contract requirements for the service frequency of the many customers that are in that territory and the products that they have on-site. Now, technicians are hitting their time windows, they’re driving fewer miles, and they’re boosting customer satisfaction.

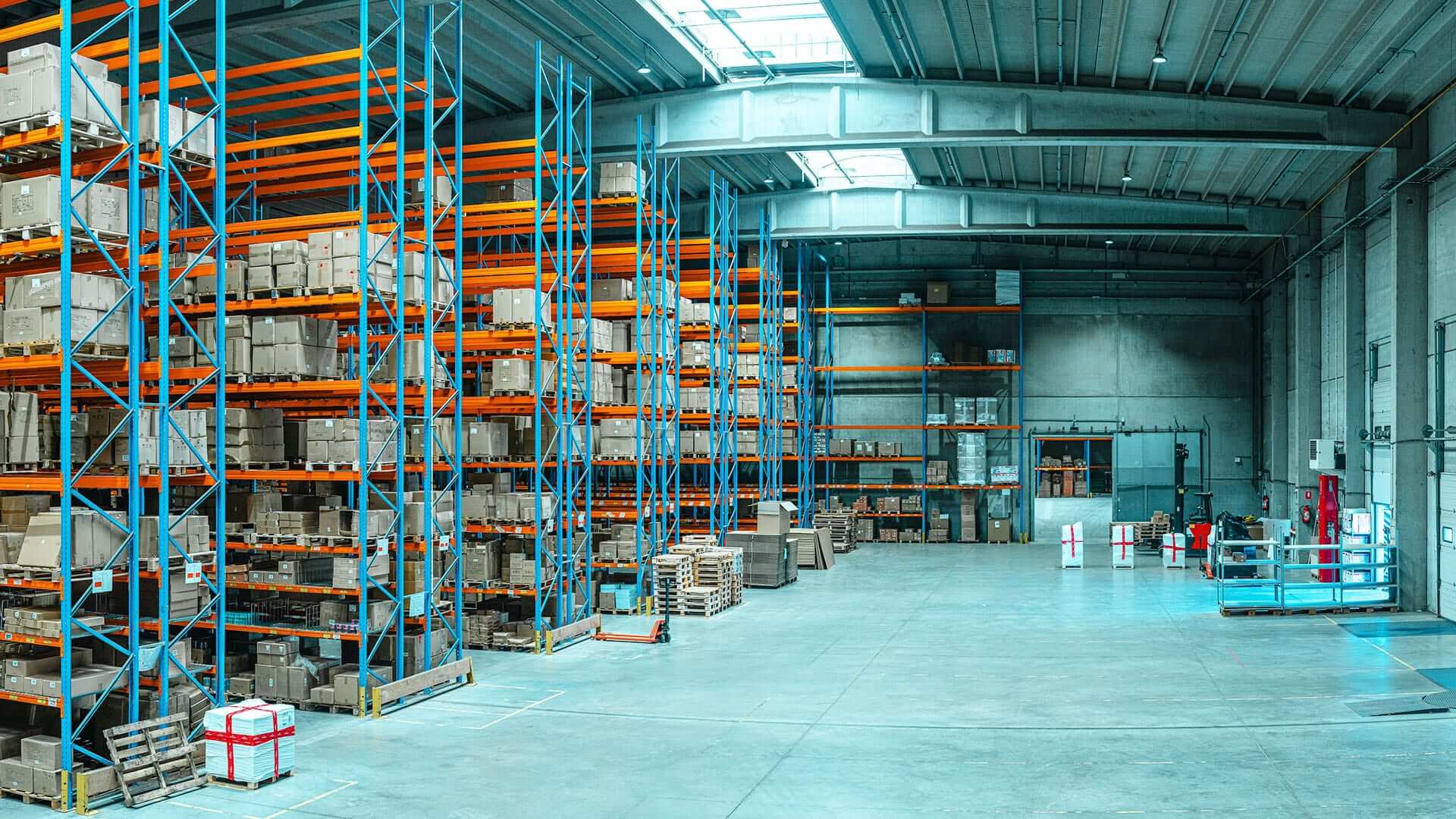

Now on the side of risk for a manufacturer, we all know that downtime is deadly. Some of the world’s leading companies minimize it by relying on geospatial analysis in their global operations centers, in their crisis management processes, or in their supply chain control towers. They’re using interactive maps to see where their suppliers, plants, distribution centers, and customers are in relationship to disruptions like floods, wildfires, or geopolitical events.

This reduces downtime at the plant or logistics center. It provides better awareness to keep associates safe, and it helps communicate with customers on their deliveries.

Chiappinelli: Interesting, crucial work on both sides, risk and delivering the customer expectations. I’m curious what you see ahead. Is there a particular use for GIS technology or location analysis that’s standing out to you?

Paripovich Stifle: Connected products are really exciting me for a couple of reasons. They’re bringing companies closer to their customers, and they’re creating new revenue streams. Knowing where the products like farm tractors, escalators, or data centers are and how they’re operating is critical to delivering service and understanding customer insights. With GIS, manufacturers can monitor the status of these products geographically, and then they can coordinate the delivery of regular maintenance and their premium service offerings.

So, some manufacturers we work with are taking this even to the next level, and they’re creating products that understand the local conditions, the local environment. And they might be encouraging a customer to be mindful of local resources, like if there’s a water shortage, or a wildfire risk, or inclement weather. I’m excited about this because I think services like these are going to really become way more widely available.

Chiappinelli: That’s really interesting. That digital connection to customers is becoming a sandbox for innovation in a lot of ways. Thank you for that context, Nikki.

Paripovich Stifle: My pleasure.

Chiappinelli: If you are interested in learning more about geospatial technology in manufacturing, check out the URL on the screen. Or if you’re watching us on WhereNext, you should be able to click the link in the article. For the WhereNext Fast Four series, I’m Chris Chiappinelli. Thanks for joining us.